Understanding the Vw Connector: Key Features and Applications Explained

Table of Contents

- Key Characteristics of the VW Connector: A Comprehensive Overview

- Exploring the Different Types of VW Connectors in the Market

- Applications of VW Connectors in Modern Technology and Industries

- Advantages of Using VW Connectors: Reliability and Efficiency

- Comparative Analysis: VW Connectors vs. Other Connector Types

- Installation and Maintenance Tips for VW Connectors: Best Practices

- Revolutionizing Automotive Connections: Insights from the Global Automotive Connector Market Report 2023 on AMPSEAL Series Advantages

- FAQS

- Conclusion

- Related Posts

You know, in today’s fast-paced world of automotive tech, connectors are a big deal. They’re really the unsung heroes when it comes to keeping everything communicating smoothly and powering up all those different systems in a vehicle. One connector that’s been catching quite a bit of attention lately is the Vw Connector. People are talking about it a lot because it’s pretty versatile and performs really well. If you look at industry forecasts, the market for these automotive connectors is expected to hit around USD 24.27 billion by 2026. That’s mainly thanks to the growing demand for more advanced vehicle features and all those electric cars popping up everywhere. Companies like Yueqing Xulian Electronics Co., Ltd. are leading the charge—they’re known for making top-notch high-tech connectors, including the Vw Connector.

What’s cool about this product is that it not only makes data transfer in ECU systems more efficient but also boosts the overall dependability of automotive wiring of all kinds. If you’re an engineer or designer working on the next vehicle, understanding what makes the Vw Connector special and where it fits in is pretty much essential for staying ahead with the latest tech.

Key Characteristics of the VW Connector: A Comprehensive Overview

The VW Connector is pretty much a must-have in a ton of electrical and electronic setups. People love it because it’s super sturdy and works efficiently. One of the things that makes it stand out is just how versatile it is; you can set it up in different ways, which means it can be used in a bunch of different devices and systems. That’s a huge plus, especially in things like cars or industrial automation where you often need various types of connections.

Another thing worth mentioning is how reliable it is, even when the environment gets rough. It’s built to handle extreme temperatures and tough conditions, so it keeps working smoothly no matter what. That’s especially important in cars, where vibrations and moisture are pretty much guaranteed. Plus, it’s actually pretty easy to install and maintain, which helps cut down on downtime. All in all, it’s a go-to choice for manufacturers who want something durable and efficient for their projects.

Understanding the VW Connector: Key Features and Applications Explained

| Feature | Description | Applications |

|---|---|---|

| Durability | Designed to withstand harsh environmental conditions. | Automotive, Industrial equipment |

| Versatility | Compatible with various connection technologies. | Consumer electronics, Telecommunications |

| Ease of Installation | Simple clip-on design for quick assembly. | Home appliances, Medical devices |

| Electrical Performance | High conductivity for efficient power and signal transfer. | Electrical systems, Automation technologies |

| Safety Features | Integrated protections against shorts and overloading. | Industrial machinery, Renewable energy systems |

Exploring the Different Types of VW Connectors in the Market

Lately, automotive tech has really been changing fast—especially with the surge of electric vehicles like the ID.3. It’s pretty crazy how many big-name brands are jumping on the electric bandwagon now. Because of that, it’s super important to get a handle on the different types of connectors used in these new cars. VW connectors, for example, are essential—they make sure that the communication and power transfer between all those tiny electronic parts work smoothly. As cars become more complex and energy efficiency becomes more critical, the need for reliable, high-quality connectors is only growing. Industry reports say that by 2025, the market for automotive connectors might hit around $30 billion—showing just how vital these little components are in the shift to electric vehicles.

When it comes to the actual connectors, VW's models are designed to withstand tough conditions—they're built to last and be dependable. Companies like Xulian, who are into making advanced automotive connectors and parts, are right in the thick of this growth. They focus on creating compact, lightweight pieces—like ECU connectors and wiring harnesses—that help electric systems in cars like the ID.3 work more efficiently and safely. As electric cars become more common, new and innovative connector solutions will be key—they’ll help push automotive tech forward and make vehicles better for both manufacturers and drivers alike.

Applications of VW Connectors in Modern Technology and Industries

You know, VW connectors are pretty much a big deal in today’s tech scene, popping up all over the place—especially in cars and other industries that rely on smooth, stable connectivity. With all these crazy advances like 5G and self-driving cars, the need for reliable and sturdy connectors has skyrocketed. I read somewhere that the global market for automotive connectors is expected to hit around $23.5 billion by 2027, mainly thanks to innovations in electric vehicles and smarter transportation options.

In the world of autonomous vehicles, VW connectors are what make real-time data flow possible—allowing sensors to chat with control units without a hitch. This keeps things safe and running efficiently. Plus, with edge computing now a thing, it’s like these cars can talk to each other and their surroundings faster and more smoothly—latency gets cut down, and performance gets a boost. Trends in tech show that all these innovations are changing the game, with connectors playing a pretty central role in how vehicles interact with their environment.

And it’s not just cars, either. More and more industries are jumping on the bandwagon, using VW connectors to power the growing array of smart gadgets and IoT devices. As connected devices become a norm, the need for fast data transfer and reliable power distribution is more important than ever. Experts say the IoT market might top $1 trillion by 2026, highlighting how crucial connectors will be in pushing these tech advancements across different sectors.

Advantages of Using VW Connectors: Reliability and Efficiency

VW connectors are pretty well known for being reliable and efficient, making them a go-to choice in lots of different setups. One of the best things about them is their tough design—they stay secure even when things get pretty rough out there. These connectors are built to handle tough conditions, like extreme heat or moisture, which helps prevent any unexpected failures. That kind of durability is especially important in automotive stuff, where safety and performance really matter.

But it's not just about being tough. VW connectors are also super easy to install and maintain. They’re designed for quick setup and take-down, which means less time spent messing around during repairs or adjustments. Plus, their design helps prevent wrong connections, so everything runs more smoothly and efficiently. Using VW connectors can really help industries run more seamlessly, cut down on costs, and boost productivity—all while lowering the chances of equipment hiccups. That’s why they’re so popular in fields like automotive, industrial machinery, and renewable energy—anywhere that solid, reliable connectivity really counts.

Comparative Analysis: VW Connectors vs. Other Connector Types

When you're comparing VW connectors to other types out there, it's really important to think about how they fit into the bigger picture of electric vehicle infrastructure. You know, as the push for cars with zero or ultra-low emissions keeps gaining momentum, having reliable and efficient connections isn’t just a nice-to-have—it’s absolutely crucial. VW connectors stand out because they’re built for durability and are compatible with a variety of charging systems, which really helps smooth out the transition for the auto industry.

**Tip:** When you're choosing connectors for EVs, make sure to check the specifications and see how well they work with your current setup. Strong, reliable connections can make a big difference in charging speed and overall vehicle performance.

And hey, it’s interesting to note that the way connectors are designed can sometimes be inspired by advances in building materials—think of things like composite walls that are both sturdy and flexible. The rise of new connection types, whether rigid or ductile, really shows how important it is to balance durability with flexibility. Similarly, VW connectors need to have that high-performance edge to keep up with the fast-changing demands of modern cars.

**Tip:** Keep yourself updated on the latest connector tech and materials so that your setups are ready for whatever the future throws at us—more efficiency, better performance, and all that good stuff.

Installation and Maintenance Tips for VW Connectors: Best Practices

When you're installing VW connectors, it’s super important to stick to best practices. Honestly, if you don’t, you could end up messing with the system’s reliability. Some reports even say that poor installation can bump failure rates up to 30%, which is pretty significant. To avoid that, just make sure to follow the manufacturer’s instructions carefully—things like lining things up correctly, not over-tightening, and using the right tools are key. It’s those small details that make all the difference.

Also, don’t forget, regular check-ups can really go a long way in making your connectors last longer. According to the IEEE, routine inspections can prevent up to a quarter of potential failures—that’s a lot! So, it’s a good idea to look out for signs of wear or corrosion, and clean them with products suited for the job. Plus, if you can control the environment—like keeping away from extreme temperatures and moisture—that can really preserve the connectors’ lifespan. Some data even suggests that connectors kept in good conditions last up to 40% longer than those living in harsh environments. Sounds like a no-brainer, right?

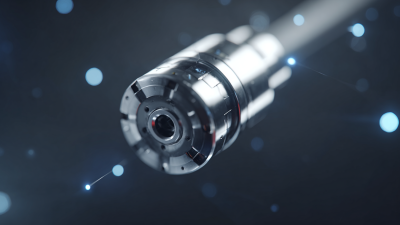

VW Connector Features and Applications

This chart illustrates the key features and applications of VW Connectors based on their popularity and usage in various automotive sectors.

Revolutionizing Automotive Connections: Insights from the Global Automotive Connector Market Report 2023 on AMPSEAL Series Advantages

The automotive industry is witnessing a significant transformation driven by advancements in connectivity and high-performance components. The 2023 Global Automotive Connector Market Report highlights the crucial role of connectors in revolutionizing automotive systems. Among the leading products is the AMPSEAL Series, which offers robust performance in harsh environments, ensuring reliability and durability for automotive applications.

One of the key advantages of the AMPSEAL Series is the rigorous testing protocols we implement. Utilizing a wide range of testing instruments, we ensure our products meet the highest quality standards. This dedication to quality is further supported by our professional technical team operating under ISO 9001 and IATF 16949 management system certifications. Our commitment to excellence not only enhances the safety and efficiency of automotive systems but also aligns with the industry's shift towards smarter, interconnected vehicles.

In addition to quality, the AMPSEAL Series is known for its quick delivery times and exceptional after-sale service, which are critical in maintaining the pace of innovation in the automotive sector. As vehicles become increasingly reliant on electronic systems, incorporating reliable connectors like the AMPSEAL Series is essential. This PCB mount header, designed with a right-angle configuration, exemplifies our focus on optimizing space while maintaining superior functionality, making it an ideal choice for modern automotive applications.

FAQS

: The main advantages of VW connectors include their reliability, robust design for secure connections in harsh environments, and efficiency in installation and maintenance.

VW connectors are engineered to withstand extreme temperatures and moisture exposure, significantly reducing the risk of failure in challenging conditions.

Their durability and reliability are crucial in automotive applications where safety and performance are paramount, ensuring consistent operation under demanding circumstances.

VW connectors feature a user-friendly interface for quick assembly and disassembly, which helps significantly reduce downtime during maintenance activities.

Their robust and efficient connectivity is particularly beneficial in sectors like automotive, industrial machinery, and renewable energy, improving productivity and reducing equipment failure risks.

VW connectors offer enhanced reliability and compatibility with various charging systems, making them essential for supporting the shift towards zero and ultra-low tailpipe emissions vehicles.

It's important to assess the specifications and compatibility of connectors with existing infrastructure to ensure robust connections that impact charging efficiency and vehicle performance.

The emergence of rigid and ductile connection types highlights the necessity for durability and flexibility in design, similar to advancements in materials like assembled composite walls.

Staying informed about the latest connector technologies and materials is crucial for ensuring that applications meet future standards and efficiency needs.

Conclusion

So, I read this blog called "Understanding the Vw Connector: Key Features and Applications Explained," and honestly, it's a pretty good deep dive into VW Connectors — those little components that are actually a big deal across many industries. It kicks off with a solid overview of what makes VW Connectors tick, then dives into the different types out there, almost like a market tour. The article also touches on how these connectors are used in today’s tech world, especially in cars, showing how they help make systems more reliable and efficient.

What’s pretty helpful is it also compares VW Connectors to other kinds, pointing out why they might be a better choice in certain situations. Plus, they give some practical tips on installing and maintaining them — stuff that matters if you actually want your connectors to perform well over time. Oh, and Yueqing Xulian Electronics Co., Ltd. gets a mention as a top-tier manufacturer, really emphasizing how crucial these connectors are for modern connectivity. Overall, it’s a nice mix of technical info and real-world advice, making it easy to get why VW Connectors are such a big deal these days.

Related Posts

-

Exploring Innovative Female Connector Applications in Modern Technology

-

5 Essential Factors to Consider When Choosing Best Cables And Connectors

-

China's Premier Export of Best Wire Pin Connectors Leading the Global Market

-

Exploring Future Trends in 2025 How to Choose the Best Connector for Your Needs

-

How to Choose the Right Automotive Electrical Connectors for Your Projects

-

Maximize Your Business Potential: Discover the Surge in Global Buyers at the 137th Canton Fair

Blog Tags: