Ultimate Guide to Choosing the Right Terminal Block Connector for Your Needs

Table of Contents

- Understanding Terminal Block Connectors: Types and Applications

- Key Industry Standards for Terminal Block Connectors

- Evaluating the Material: Brass vs. Copper in Terminal Blocks

- Electrical Ratings: Choosing Connectors for Optimal Performance

- Factors Influencing Terminal Block Connector Lifespan and Reliability

- Cost Analysis: Budgeting for Quality Terminal Block Solutions

- Revolutionizing Connectivity: Exploring the AMP MCP Connector System Series for Enhanced Performance and Reliability

- FAQS

- Conclusion

- Related Posts

In the fast-changing world of electronics, picking the right Terminal Block Connector really matters if you want your projects to be reliable and perform well. I recently came across a report that says the global market for these connectors is expected to hit around $2.5 billion by 2026 — pretty impressive! This boom’s largely due to the growing need for solid electrical connections in everything from cars and industrial setups to everyday consumer gadgets.

Yueqing Xulian Electronics Co., Ltd. is definitely riding this wave. They offer a pretty wide range of quality automotive connectors, ECU connectors, terminals, wiring harnesses, and all sorts of accessories. What’s cool is that they’re big on innovation, constantly pushing to improve their production and R&D. That really helps engineers and designers make smarter choices when selecting Terminal Block Connectors tailored to their needs.

It’s all about pushing technology forward and making connections better, one small component at a time.

Understanding Terminal Block Connectors: Types and Applications

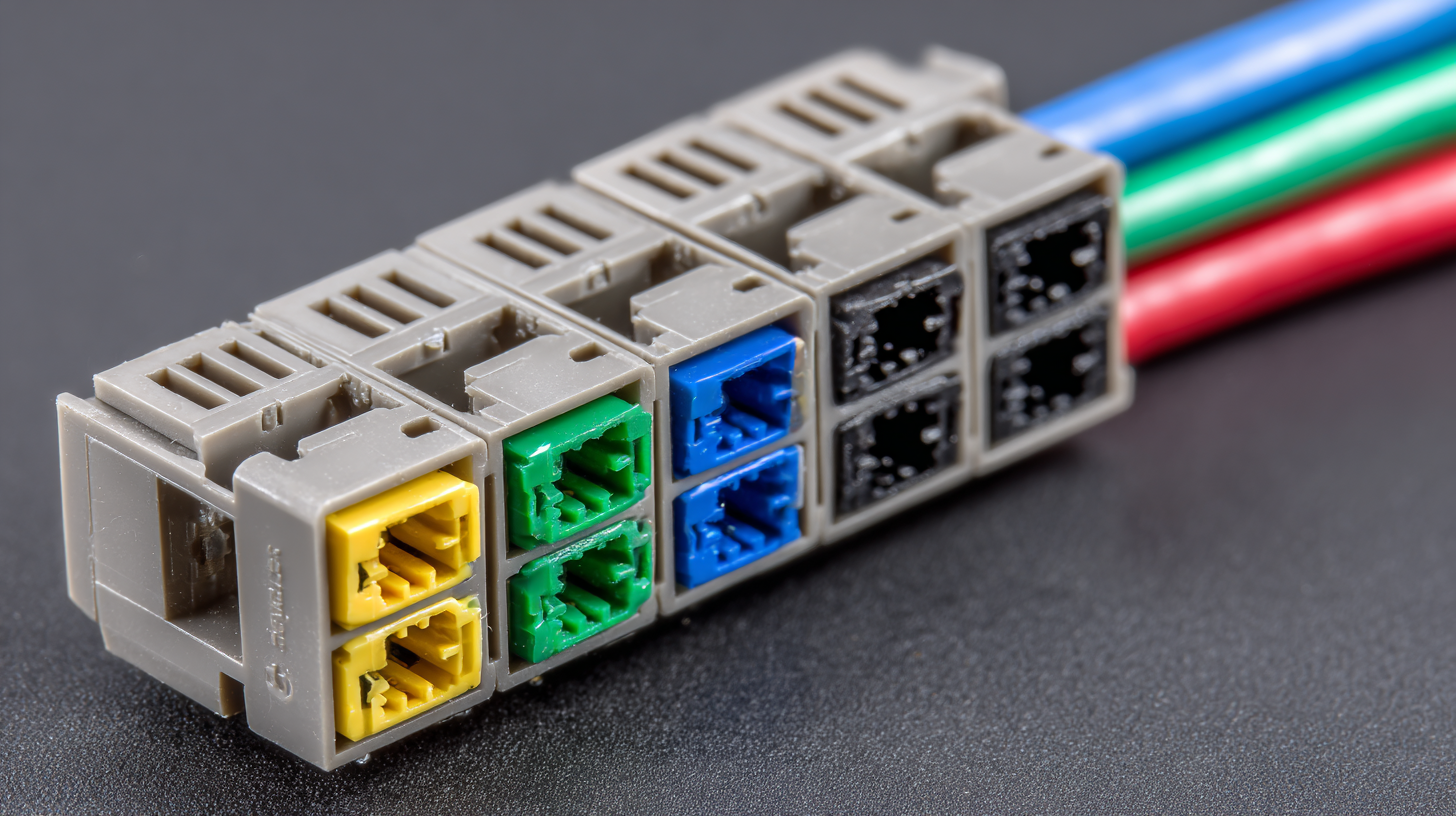

Terminal block connectors are pretty much essential when it comes to electrical and electronic systems. Basically, they're the points where wiring and circuit paths come together. You can find different types out there, each one suited for specific jobs. Getting a good grip on the differences—like screw terminal blocks, spring-clamp ones, or push-in types—can really make a big difference in how reliable and efficient your setup turns out to be.

Terminal block connectors are pretty much essential when it comes to electrical and electronic systems. Basically, they're the points where wiring and circuit paths come together. You can find different types out there, each one suited for specific jobs. Getting a good grip on the differences—like screw terminal blocks, spring-clamp ones, or push-in types—can really make a big difference in how reliable and efficient your setup turns out to be.

Screw terminal blocks are kinda the classics—super sturdy and reliable, especially when you need a secure connection that can handle tough environmental conditions. Spring-clamp terminal blocks are great if you're after quick assembly and easy wire insertion—super handy when you're trying to save time. Then there are push-in terminal blocks, which are all about simplicity—they don’t even need tools, making the whole process much faster. Each of these has their own perks and best-use scenarios, whether it’s industrial machinery, building automation, or even automotive systems. Picking the right one really depends on what you're working on, so it’s worth understanding what each type offers.

Key Industry Standards for Terminal Block Connectors

When you're picking out terminal block connectors, it's pretty important to get a good grasp of the main industry standards. Why? Because that’s what ensures your connections stay solid across different kinds of projects. Terminal blocks are those modular little devices that help securely connect multiple wires—usually with some kind of clamping mechanism to keep everything stable. Fun fact: the global wire connector market is expected to grow at about 5.9% annually and hit around $94.7 billion by 2035. That really shows how much demand there is for reliable connectors in all kinds of industries.

Here's a tip: always think about what you're actually working on when choosing terminal block connectors. Different applications call for different insulation types and materials—so pick what fits best. For example, low-voltage electrical connectors are expected to see big growth in Latin America, which makes it all the more important to follow regional standards to stay compliant.

And don’t forget—keeping an eye on leading manufacturers can give you a good sense of who's innovating and producing quality stuff. These top players set the bar in the industry, so understanding what they offer can make your life easier when it comes to picking the right connectors for your project. Plus, with new tech constantly coming out—like improvements in wire-to-board connectors and pogo pins—staying updated can really make a difference in ensuring your setups are future-proof and up to speed.

Evaluating the Material: Brass vs. Copper in Terminal Blocks

When you're choosing terminal block connectors, one of the most important things to think about is the material they're made of — especially when comparing brass and copper. Brass, which is mostly copper mixed with zinc, strikes a pretty good balance between conductivity, strength, and resistance to corrosion. Plus, it's usually more affordable, so it’s a popular pick for a bunch of different projects, especially if you're watching your budget. Now, it doesn’t quite conduct electricity as well as pure copper, but its durability and ability to withstand wear and tear can make it a great choice, especially in tough environments where robustness really matters.

On the flip side, copper is pretty much considered the gold standard in electrical conductivity. It offers top-notch electrical performance, which means less energy gets lost along the way. That’s why copper terminal blocks are often the go-to for high-performance stuff, like power generation and distribution systems. But, a little heads up — copper tends to oxidize over time, especially if it’s in certain environments, so people often use coatings or treatments to help it last longer. At the end of the day, deciding between brass and copper really depends on what your specific needs are — things like electrical performance, the environment, and how much you're willing to spend all come into play here.

Electrical Ratings: Choosing Connectors for Optimal Performance

When you're choosing terminal block connectors, it's really important to get a good handle on their electrical ratings. Not all connectors support the same voltage and current levels, so picking the right one for your specific setup can save you a lot of hassle down the line. For example, if you're working with high-voltage stuff, make sure to go for connectors rated for higher voltages—trust me, safety and reliability depend on it.

Here's a little tip: always double-check the manufacturer's specs for voltage and current ratings. It’s a good idea to pick connectors that can handle a bit more than your maximum expected load—that way, you steer clear of overheating and extend the life of your connections.

Also, don’t forget to think about where these connectors are gonna be used. If they’re exposed to things like moisture or extreme temperatures, you’ll want to pick ones with the right ratings and materials that can stand up to corrosion or damage.

Another tip—look for connectors with IP ratings. They tell you how well the connectors are protected against dust and water. And of course, always check the product datasheets to make sure they’re a good fit for your environment. Better to be safe than sorry!

Factors Influencing Terminal Block Connector Lifespan and Reliability

So, when you're choosing a terminal block connector, it’s pretty important to get a good handle on what actually affects its lifespan and how reliable it’s gonna be. I came across some info from the Electronic Industries Alliance, and it turns out the lifespan can really vary — we're talking anywhere from around 10,000 to over 50,000 mating cycles. A big part of that depends on things like what materials are used, how you install it, and the environment it’s in. For example, connectors made from top-notch thermoplastic tend to handle heat and moisture way better, which means they usually don’t wear out as quickly.

Quick tip: Think about where you’ll be using the connector. Things like super high or low temperatures, humidity, or exposure to stuff that can cause corrosion can seriously cut down how long it lasts.

Also, the way a connector’s made makes a big difference. The International Electrotechnical Commission did some research and found that connectors built with stricter quality control often have about 30% fewer failures. So, if you go for brands that really test their products and stick to standards, you’re more likely to get something that’ll work reliably over time.

Another tip: When you pick out connectors, try to find ones with detailed testing reports and certifications. Those little extras can tell you a lot about how durable and trustworthy they’ll be in your particular setup.

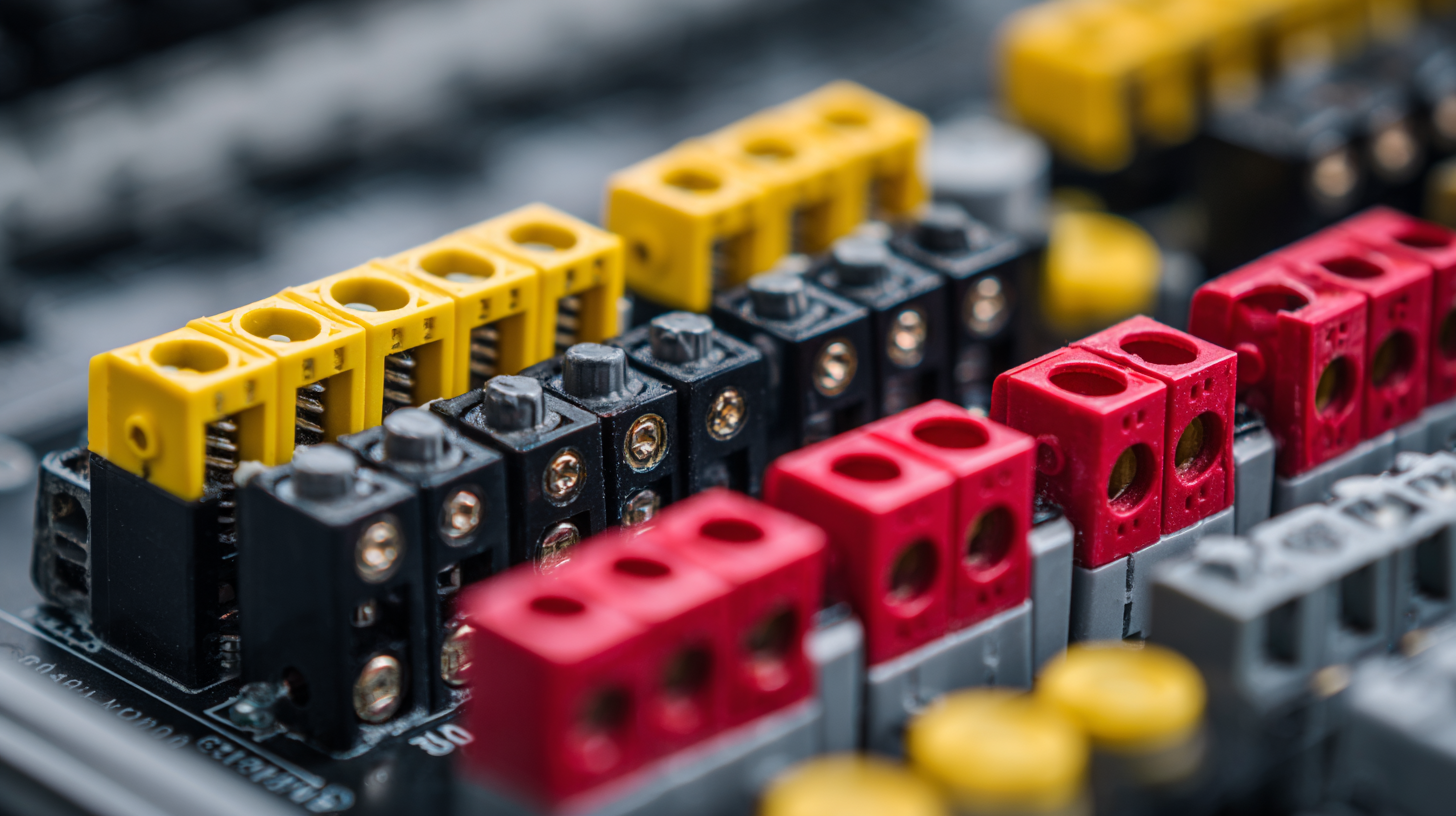

Ultimate Guide to Choosing the Right Terminal Block Connector for Your Needs

| Connector Type | Material | Rated Current (A) | Temperature Range (°C) | Lifespan (cycles) | Application |

|---|---|---|---|---|---|

| Screw Type | Brass | 30 | -40 to 105 | 100,000 | Industrial Equipment |

| Spring Clamp | Copper | 25 | -20 to 85 | 50,000 | Automation Systems |

| Push-In | Tin-Plated Copper | 20 | -25 to 90 | 60,000 | Home Appliances |

| Barrier | Aluminum | 15 | -40 to 80 | 30,000 | Telecommunication |

Cost Analysis: Budgeting for Quality Terminal Block Solutions

When you're budgeting for terminal block connectors, it’s not just about the sticker price upfront—think about the long-term value too. I came across a report by MarketsandMarkets that says the terminal blocks market is expected to hit around $5.37 billion by 2026. That’s huge, and it’s mainly because more industries are really pushing for reliable and efficient electrical connections nowadays. This trend just goes to show that investing in good-quality terminal blocks is worth it; they’re built to last, which can save you a bunch on replacements and ongoing maintenance in the long run.

On top of that, a lot of industry studies show that companies can cut their installation costs by up to 25% by picking terminal blocks that fit smoothly into existing systems. When you’re shopping around, make sure you’re looking for connectors made from sturdy materials—this really reduces the chance of failures that could lead to costly downtime. All in all, splurging a little on high-quality terminal blocks not only boosts your electrical system’s performance but can also be a smart move for your budget down the line.

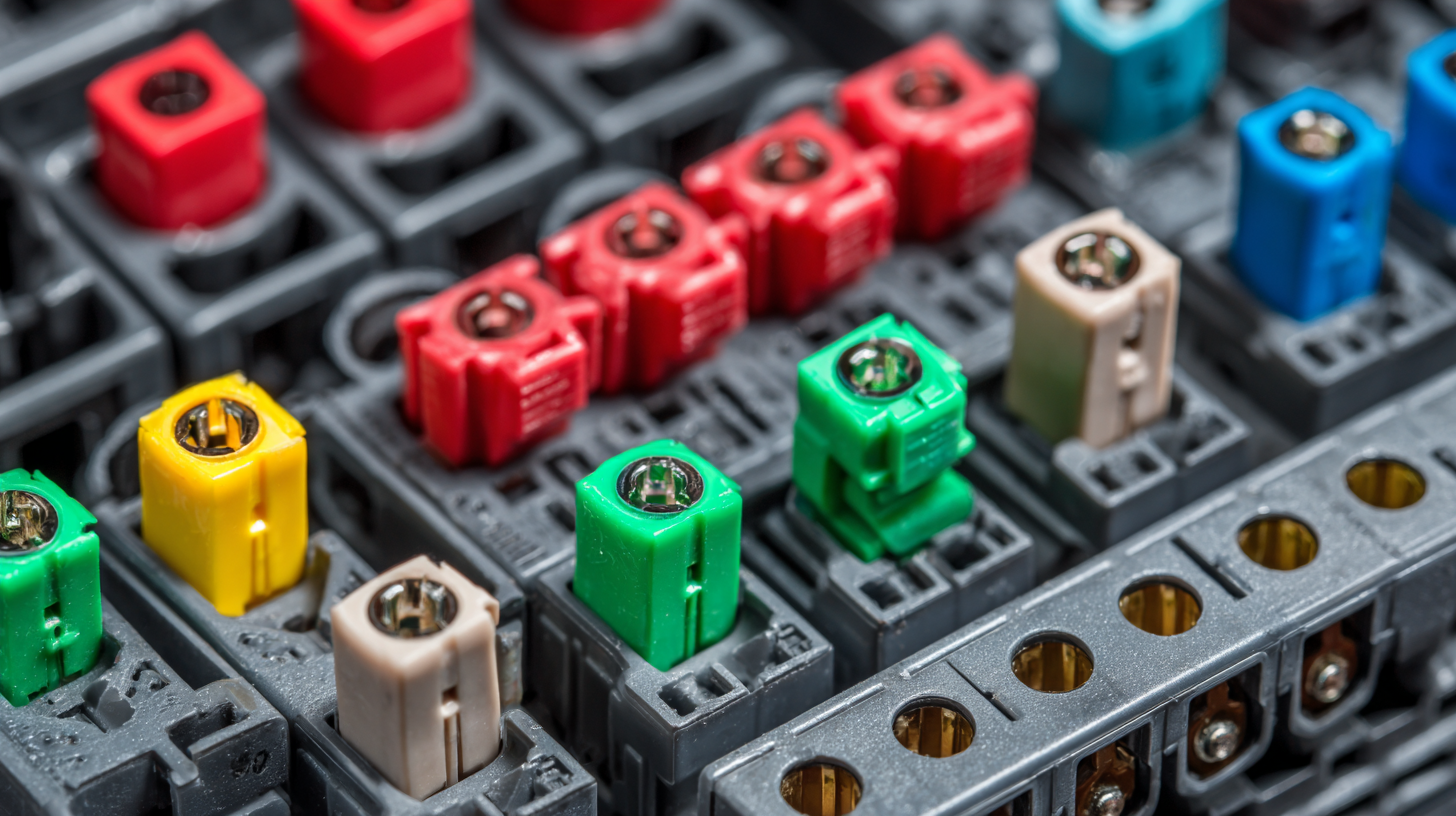

Revolutionizing Connectivity: Exploring the AMP MCP Connector System Series for Enhanced Performance and Reliability

In today's fast-paced technological landscape, connectivity plays a pivotal role in the performance and reliability of various applications. The AMP MCP Connector System Series stands out as a revolutionary solution designed to enhance these aspects significantly. This series is backed by rigorous testing protocols utilizing a wide range of instruments, ensuring that only top-quality products reach the market. This level of assurance is critical, as reliable connectivity components are vital for sectors such as automotive, telecommunications, and industrial manufacturing.

With certifications like ISO 9001 and IATF16949, our professional technical team adheres to strict management system standards, reinforcing our commitment to excellence in both product performance and manufacturing processes. Industry reports indicate that a staggering 75% of connectivity failures are linked to poor-quality components, making our focus on quality control essential for mitigating such risks. The AMP MCP Connector Series not only addresses these concerns but also promises fast delivery times and robust after-sale service, essential elements for maintaining a competitive edge in the connectivity market.

Designed with durability in mind, the stylish black housing of the connectors ensures they can withstand the rigors of various applications while maintaining a professional appearance. As reported in recent industry analyses, upticks in demand for high-performance connectivity solutions are evident, further solidifying the importance of investing in next-generation systems like the AMP MCP Connector Series. By prioritizing enhanced performance and reliability, we strive to support our clients' needs in an ever-evolving technological environment.

FAQS

: Terminal block connectors are modular devices that securely connect two or more wires, typically featuring a clamping mechanism for stability. They are essential for ensuring reliable connections in various applications across diverse industries.

The global wire connector market is projected to grow at a compound annual growth rate (CAGR) of 5.9%, reaching approximately USD 94.7 billion by 2035, reflecting the increasing demand for reliable connectors.

Always consider the specific application type, as this will guide you in choosing the right insulation and material grade suitable for that application.

The operational environment, including extreme temperatures, humidity, and exposure to corrosive substances, can drastically shorten the lifespan of terminal block connectors.

Factors influencing lifespan and reliability include the materials used, installation methods, environmental conditions, and the quality of the manufacturing process.

The average lifespan of a terminal block connector generally ranges from 10,000 to over 50,000 mating cycles, depending on various factors.

Look for connectors from reputable brands that prioritize rigorous testing and compliance, as they tend to exhibit a reduction in failure rates.

Knowledge about leading manufacturers provides insights into quality and innovation, which can help you select connectors that meet technical requirements and industry benchmarks.

Seek connectors that provide detailed testing reports and certifications, as these are key indicators of quality and longevity for your application.

Conclusion

Hey there! If you're trying to figure out how to pick the right terminal block connector for your project, our 'Ultimate Guide to Choosing the Right Terminal Block Connector for Your Needs' is just what you need. We walk you through the important stuff—like different types of connectors and what each one’s good for—so you can match them up with your specific needs without any headache. We also cover industry standards and take a close look at materials like brass and copper, so you know what impacts durability and how well they conduct electricity. Plus, we chat about electrical ratings that really matter for good performance. We even break down costs to help you plan your budget, especially if you're aiming for high-quality options. By the way, as a company that specializes in automotive connectors and other stuff, Yueqing Xulian Electronics Co., Ltd. is all about using the latest tech to craft reliable, efficient terminal block connectors designed just for you.

Hope this gives you a clearer, more friendly idea of what to look for—happy connector hunting!

Related Posts

-

Finding High Quality Suppliers for Best Automotive Crimp Connectors in a Competitive Market

-

Ultimate Checklist for Sourcing the Best Tyco Electronics Products: Key Data & Insights for Global Buyers

-

Ultimate Guide to Choosing the Best Wire Harness Connectors for Your Projects

-

Benefits of Using the Best Cables and Connectors for Optimal Performance

-

How to Choose the Best Male Female Wire Connectors for Your Projects

-

Top Approaches for Sourcing the Best Te Amp in Global Markets

Blog Tags: