How to Select the Best Connector Cable for Your Global Supply Chain Efficiency

Table of Contents

- Understanding the Different Types of Connector Cables in Supply Chains

- Key Features to Consider When Choosing Connector Cables

- Evaluating Connector Cable Durability and Compatibility

- Cost-Effectiveness: Balancing Quality and Affordability in Cables

- Best Practices for Maintaining Connector Cables in Logistics Operations

- Future Trends in Connector Cable Technology for Global Supply Chains

- FAQS

- Conclusion

- Related Posts

In today’s fast-moving world of global supply chains, picking the right connector cable isn’t just a small detail – it’s actually a pretty big deal. It can really make a difference when it comes to keeping things running smoothly and reliably. A report from Market Research Future even predicts that the worldwide connector market could hit around USD 100 billion by 2025, with plenty of demand for top-notch, specialized connector solutions. As a leader in this field, Yueqing Xulian Electronics Co., Ltd. focuses on automotive connectors, ECU connectors, terminals, wiring harnesses, and all those other vital accessories. Choosing the right connector isn’t just about compatibility; it can actually boost performance and last longer, which means less downtime and more productivity in the long run. In this blog, I want to help guide you through the selection process so you can pick the best connectors out there and give your supply chain management a real boost.

Understanding the Different Types of Connector Cables in Supply Chains

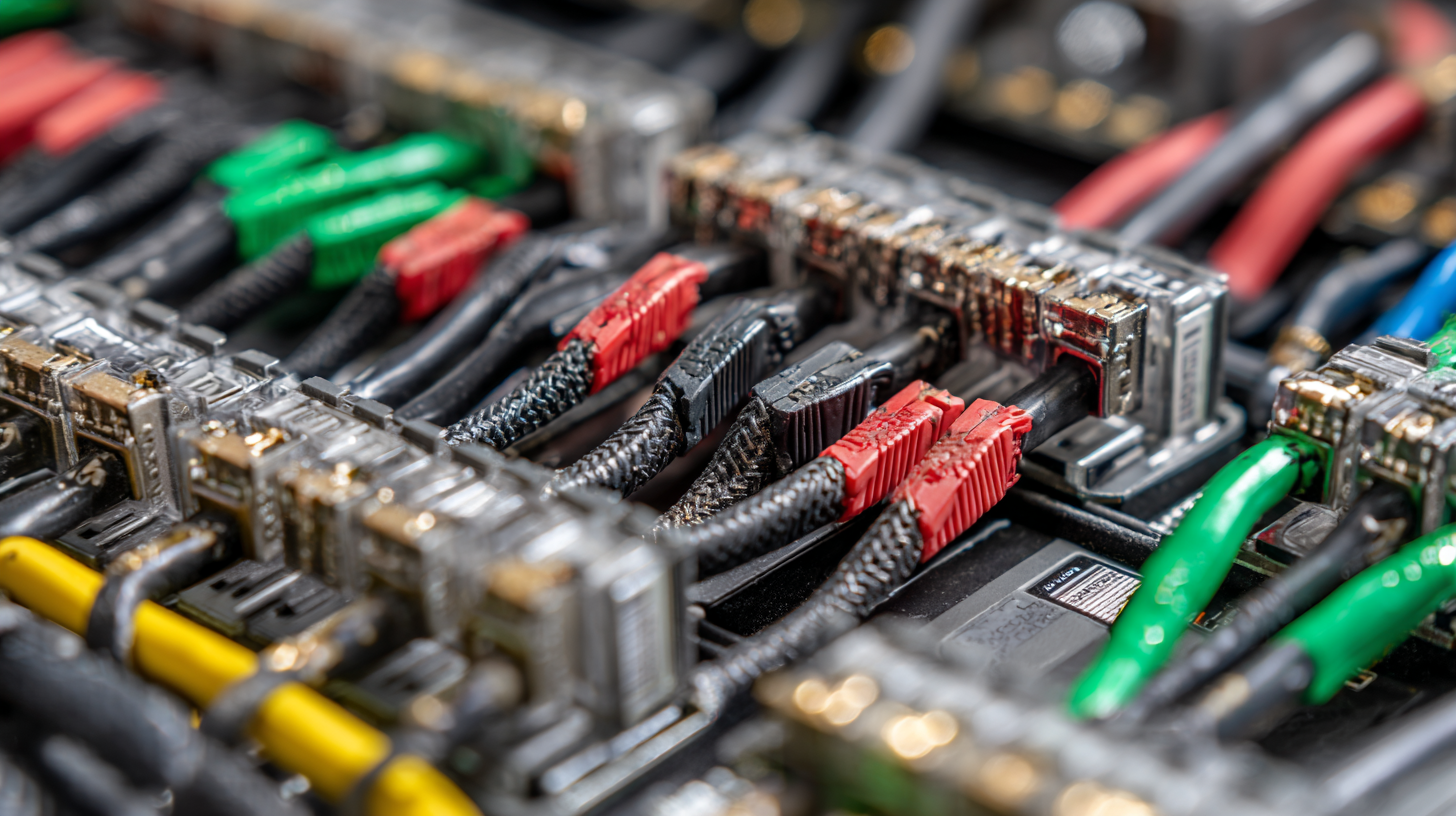

When you're handling a global supply chain, picking the right connector cable is a pretty big deal—it directly impacts how smooth and reliable everything runs. There are all kinds of connectors out there, each serving a different purpose. For example, automotive connectors need to be tough enough to handle vehicle performance, while ECU connectors are more about electronic control units. The key thing is really understanding what your specific supply chain needs so you can pick the best cable for the job.

Here's a tip: think about where those cables are going to be used. If they’re gonna be out in harsh environments — like really hot or cold spots, or places with a lot of moisture — then it’s super important to go for cables with the right insulation and protection ratings. Also, make sure the connector types will play nicely with your existing systems—that way, you avoid any headaches during installation.

And don’t forget about quality. At Yueqing Xulian Electronics Co., Ltd., we take pride in our advanced manufacturing techniques, especially for automotive connectors, wiring harnesses, and other accessories. Working with reputable manufacturers like us? It means you’re getting products that won’t let you down—durable and reliable, which in the long run keeps your supply chain running smoothly. Oh, and be sure to check on lead times and logistics, so you can plan ahead and avoid any last-minute surprises with delivery.

All in all, making the right choice when it comes to connectors can really save you hassle down the line. Just take the time to evaluate your needs, consider the environment, and partner with trusted suppliers—you’ll be good to go!

Key Features to Consider When Choosing Connector Cables

When you're picking out connector cables for your global supply chain, it’s really important to pay attention to a few key features that can make a big difference in how smoothly things run. First off, think about how durable the cable is. Depending on where they're going to be used—whether it’s in humid environments, extreme temperatures, or places with a lot of physical wear—you’ll want cables that can handle that. It’s often a good idea to go for ones that are certified for industrial use; that usually means they’re built to last longer.

Then, don’t forget about compatibility. Make sure the connector cables you pick actually work with your existing equipment and systems. That means checking not just the physical connectors but also the specs for data transfer speeds and power needs. Using incompatible cables can cause all kinds of headaches—slower operations, delays, you name it.

Tip: Think ahead about what your future needs might be. It’s smart to select cables that can support upgrades or tech changes down the line. Investing in adaptable cables now can save you a headache—and money—later on. Oh, and keep an eye on the length you need. Longer cables might cost a bit more, but they can help prevent signal loss, especially if you’re dealing with bigger setups.

Key Features to Consider When Choosing Connector Cables

This chart illustrates the importance rating of various features to consider when selecting connector cables for your global supply chain efficiency. The features evaluated include Cable Length, Material Quality, Data Transfer Rate, Durability, and Cost Effectiveness, rated on a scale from 1 to 10.

Evaluating Connector Cable Durability and Compatibility

When you’re assessing connector cables for your global supply chain, it’s super important to think about the environments where these cables will actually be used. A report from the International Electrotechnical Commission (IEC) points out that about a quarter of cable failures happen because they just aren’t resistant enough against harsh conditions. So, picking cables that can handle extreme temperatures, humidity, and mechanical wear and tear can really make your supply chain more reliable. Also, go for those that meet the IEC 60529 standard for ingress protection (IP rating) — basically, cables that can resist dust and water are a must, especially when your products are moving across all kinds of climates.

How to Select the Best Connector Cable for Your Global Supply Chain Efficiency - Evaluating Connector Cable Durability and Compatibility

| Cable Type | Durability Rating (Cycles) | Temperature Range (°C) | Compatibility | Typical Application |

|---|---|---|---|---|

| USB 3.0 | 10,000 | -20 to 80 | Computers, peripherals | Data transfer |

| HDMI | 5,000 | 0 to 70 | TVs, monitors | Audio/Video |

| Ethernet | 15,000 | -40 to 75 | Networking devices | Internet connection |

| Power Cable | 20,000 | -30 to 90 | Electrical devices | Power supply |

| Coaxial Cable | 10,000 | -40 to 60 | Communications | Signal transmission |

Cost-Effectiveness: Balancing Quality and Affordability in Cables

When you're picking out connector cables for your global supply chain, it’s really about finding that sweet spot between cost and quality. The first step is to really think about what your operation actually needs. Going for high-quality cables can make a huge difference—reliable connections mean fewer headaches, less downtime, and avoiding costly equipment breakdowns. But, let’s be honest, those top-tier options can also be pretty pricey. So, it’s worth weighing whether the extra reliability is worth the extra dollars. Sometimes, investing a bit more upfront in durable cables can save you headaches—and money—in the long run—compared to constantly replacing cheaper alternatives down the line.

On the flip side, staying within budget is super important. You want cables that are affordable but still do the job well. That often means finding suppliers who can offer some flexibility in pricing—think bulk deals or long-term contracts—that might help cut costs without skimping on quality. At the end of the day, choosing the right connector cables is all about balancing functionality, durability, and bang for your buck—so your supply chain keeps running smoothly without sacrificing quality.

Best Practices for Maintaining Connector Cables in Logistics Operations

When it comes to managing logistics, keeping connector cables in good shape really matters for smooth communication and data transfer. Doing regular maintenance not only helps those cables last longer but also keeps the whole supply chain running more efficiently. It’s one of those little things that makes a big difference!

**Tip 1:** Make it a habit to check your cables regularly for any signs of damage—things like frayed wires or brittle insulation. Setting up a routine for inspecting and swapping out damaged cables can save you from unexpected hiccups that might throw a wrench in your operations.

**Tip 2:** Staying organized is key. Store your cables properly and try using cable management tools to avoid tangles and bends. Over time, this kind of care prevents performance issues and keeps everything working smoothly.

**Tip 3:** Don't forget to train your team! Educate everyone on why proper cable handling matters and share best practices. When folks know how to handle and install cables correctly, you cut down on mishaps that can cause costly downtime. Trust me, a little training pays off big time in the long run.

Future Trends in Connector Cable Technology for Global Supply Chains

Looking ahead, the future of connector cable tech is really going to shake up how global supply chains work. As manufacturing keeps evolving, we're starting to see some pretty cool trends that will boost supply chain resilience — and at the same time, help cut down on environmental impact. One big thing to watch is how manufacturers are starting to use smarter, eco-friendlier materials in making cables. These new materials don’t just last longer; they also lower the carbon footprint, which is pretty awesome. More companies are picking green options, aligning their tech with sustainability goals — no surprise there.

And there's more: AI-driven analytics are becoming a game changer for managing cables and supply chains. By tapping into real-time data, businesses can fine-tune their operations, spot potential failures before they happen, and keep networks running smoothly. Honestly, this kind of tech is super important right now, especially since global markets are getting more complicated than ever.

Heads up: When you're choosing connector cables, think about how long they’ll last and whether the materials are eco-friendly. Go for options that give you solid performance but also show a commitment to sustainability. And don’t forget to check out solutions that use AI — they can really make your supply chain more efficient and responsive to whatever the market throws at you.

FAQS

: The article mentions automotive connectors and ECU connectors, which serve distinct functions in maintaining vehicle performance and supporting electronic control units.

Considering the environment is crucial because exposure to harsh conditions like extreme temperatures or moisture requires appropriate insulation and protective ratings for the cables.

High-quality manufacturing ensures that the connector cables are durable and reliable, enhancing overall supply chain efficiency and reducing the risk of failures.

Key features include durability, compatibility with existing systems, support for future upgrades, and appropriate cable length to prevent signal loss.

Using incompatible connector cables can lead to inefficiencies and delays, as they may not meet the specifications required for data transfer rates and power needs.

Key trends include the use of advanced, eco-friendly materials to enhance durability and the integration of AI-driven analytics for optimizing cable management and supply chain operations.

Companies should look for cables made from sustainable materials and those designed to reduce their carbon footprint in alignment with environmental goals.

AI-driven analytics can help companies optimize supply chain operations, predict failures, and ensure smoother connectivity, thus enhancing overall efficiency.

Companies should choose cables that support upgrades or changes in technology, which allows for flexibility and can prevent costly replacements in the future.

Evaluating lead times and logistics is essential to ensure the seamless delivery of connector cables, which directly affects the efficiency and reliability of the supply chain.

Conclusion

In today's fast-moving world of global supply chains, picking the right connector cable isn't just a small detail — it's actually pretty important for keeping things running smoothly and reliably. I think the first step is really understanding the different types of connector cables out there. Each one has its own perks, tailored for different uses, so it’s worth taking the time to get familiar with them. Things like how tough they are, whether they fit with your existing setups, and how much they cost are all key points to think about. You want to find that sweet spot between good quality and affordability, right?

And let’s not forget — taking good care of your connector cables with some simple maintenance tips can really make them last longer and perform better, especially when you’re dealing with logistics. Looking ahead, new tech developments in connector cables are pretty exciting — they might just change how we handle connectivity in supply chains. Here at Yueqing Xulian Electronics Co., Ltd., we’re really proud of our top-notch automotive connectors and wiring harnesses. Our goal is to make sure our customers always get the best solutions for their connector needs — because we know how crucial that stuff is.

Related Posts

-

10 Essential Tips for Choosing the Best Wire Cable Connectors

-

5 Essential Factors to Consider When Choosing Best Cables And Connectors

-

China's Exquisite Legacy in Best Wire Cable Connectors Leading the Export Arena

-

Ultimate Guide to Choosing the Right Connector Cable for Your Industrial Needs

-

Exploring Innovative Female Connector Applications in Modern Technology

-

Top 10 Electrical Box Connector Manufacturers from China at the 137th Canton Fair

Blog Tags: