Ultimate Guide to Choosing the Right Connector Cable for Your Industrial Needs

Table of Contents

- Understanding the Importance of Connector Cables in Industrial Applications

- Common Issues Encountered with Different Types of Connector Cables

- Factors to Consider When Selecting Connector Cables for Industrial Use

- Comparative Analysis of Popular Connector Cable Types and Their Limitations

- Best Practices for Maintaining and Troubleshooting Connector Cables

- Optimizing Performance and Safety: The Essential Role of SCHUTZKAPPE F4+7P Cable Accessories in Modern Connectors

- FAQS

- Conclusion

- Related Posts

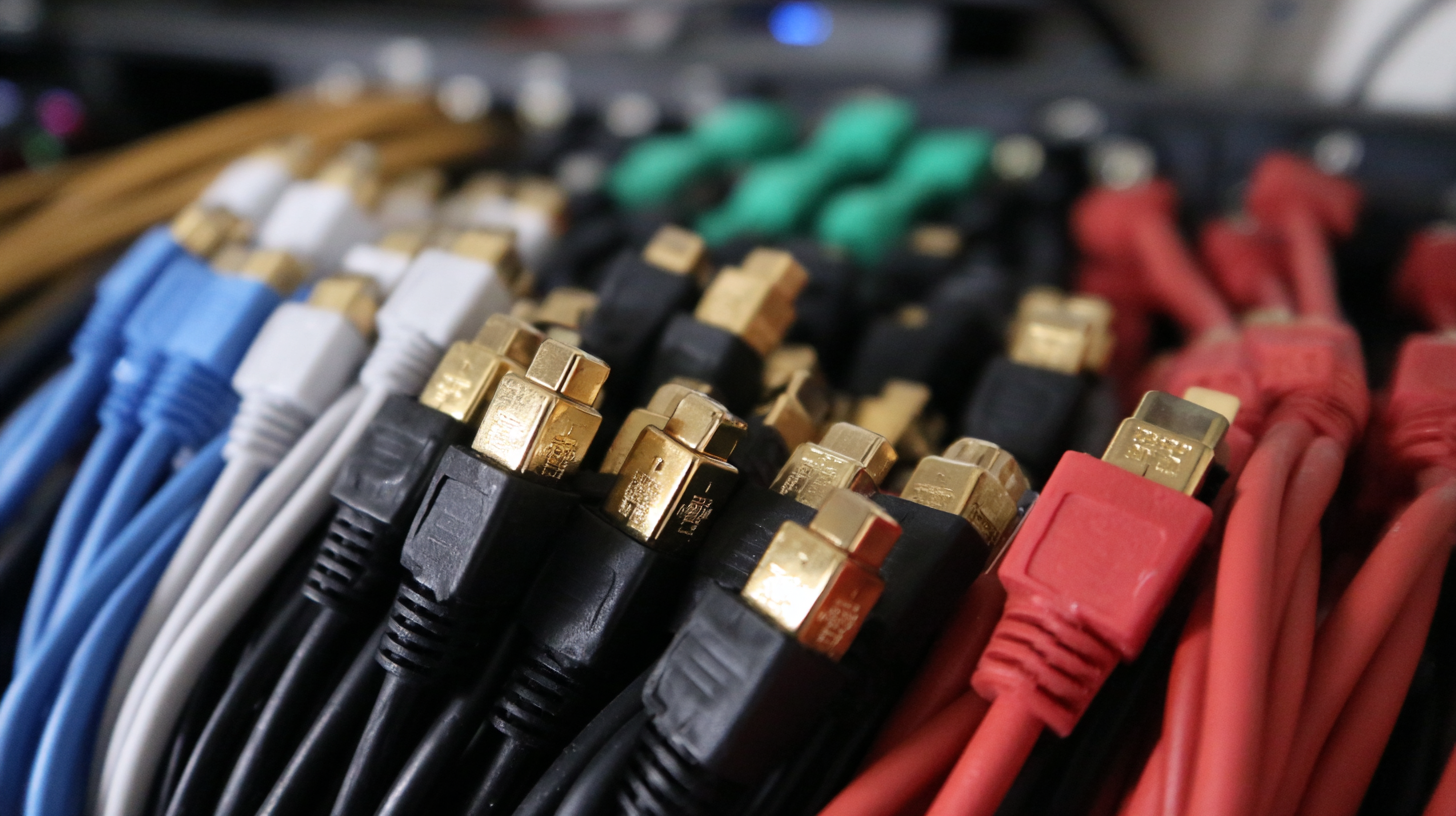

Hey there! In today’s super busy industrial world, picking the right connector cable is more important than ever. I recently came across a report by MarketsandMarkets that says the global connector market could hit around $78.4 billion by 2026. That’s mainly because everyone’s craving better interconnectivity, especially in fields like automotive and electronics. At Yueqing Xulian Electronics, we’re all about providing top-notch connector solutions—think automotive connectors, ECU connectors, wiring harnesses, you name it. As technology keeps advancing and machinery gets more complicated, choosing the correct connector isn’t just a small detail; it’s key to making everything run smoothly, safely, and reliably. This guide is here to give you the lowdown on what to consider and how to pick the right one, so you’re not left guessing. Trust me, a little effort here can make a huge difference for your projects!

Understanding the Importance of Connector Cables in Industrial Applications

Connector cables might not seem like a big deal at first glance, but trust me, they’re actually downright essential when it comes to keeping industrial systems running smoothly. Think of them as the vital link that handles both power and data transfer between machines—without them, everything can quickly fall apart. Using the wrong type of connector cable? That can cause all sorts of headaches like signal loss, more downtime than you’d like, or even damaging your gear. So, seriously, understanding how important these cables are is a must if you're working in any industrial setting.

When you’re picking out connector cables, a few things are worth keeping in mind. First off, think about where they’re going to be used. If the environment is harsh—say, super hot, super damp, or full of stuff that can cause corrosion—you'll want to go for cables that are rated for those specific conditions. That way, they last longer and stay reliable. Also, make sure they’ll play nicely with your existing equipment so you don’t end up with costly upgrades or repairs down the road.

A couple of quick tips: Measure the length you actually need—longer isn’t always better because it can cause signal issues. Check the cable’s gauge too; thicker wires conduct better but might be stiffer and less flexible. And don’t forget about the connectors—pick ones that lock securely so you don’t have to worry about accidental disconnects mid-work. All these little things make a big difference, I promise.

Ultimate Guide to Choosing the Right Connector Cable for Your Industrial Needs

| Connector Type | Application | Max Voltage (V) | Current Rating (A) | Material | Environmental Rating |

|---|---|---|---|---|---|

| M8 Connector | Industrial Sensors | 24V | 4A | Plastic | IP67 |

| M12 Connector | Automation Equipment | 60V | 4A | Metal | IP67 |

| DIN Connector | Power Supply | 230V | 16A | Plastic | IP20 |

| RJ45 Connector | Data Transmission | 60V | 1A | Plastic | IP20 |

| USB Connector | Device Charging | 5V | 3A | Plastic | IP20 |

Common Issues Encountered with Different Types of Connector Cables

When you're picking out connector cables for industrial stuff, it’s really important to understand the common issues that can pop up with different types. One major concern that's been coming up a lot in recent industry reports is the mechanical stress on connectors—that's the kind of strain from vibrations or constant movement that can cause connectors to fail way earlier than they'd normally should. Actually, a study by the International Electrotechnical Commission (IEC) found that nearly 30% of connector failures are linked directly to this kind of stress. So, making sure you select a cable that's suited for the environment it’ll be used in can really help it last longer and boost its overall reliability.

Another big hiccup folks run into is compatibility—basically, using the wrong types of connector cables together. According to the IEEE, about 20% of connectivity issues in industrial setups happen because people are mismatching connectors. That can lead to poor signal quality, higher resistance, and even overheating. With the push towards automation and IoT, it’s more important than ever to pick the right connectors that meet both the mechanical and electrical needs. Doing so helps keep things running smoothly and cuts down on downtime.

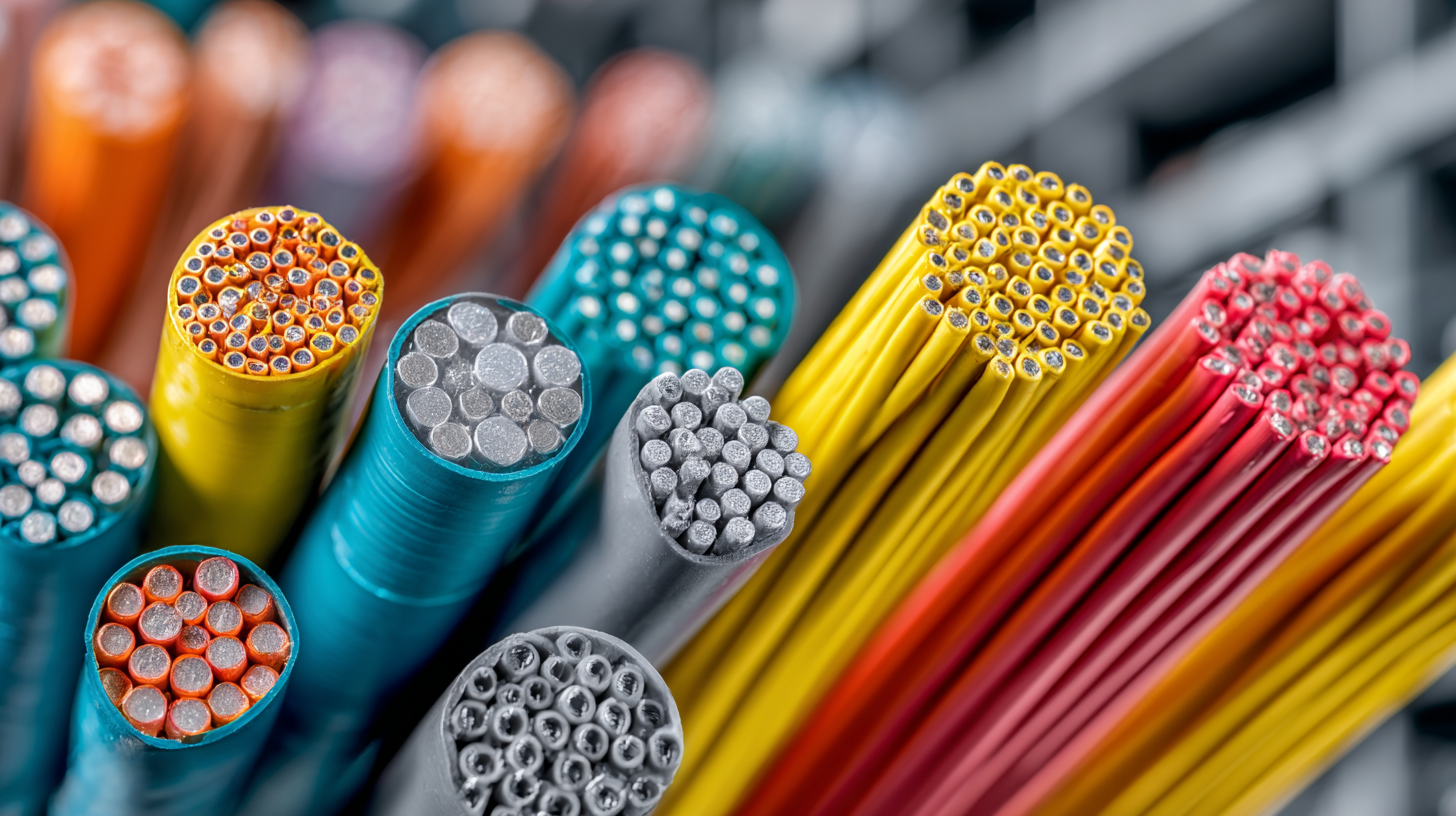

Factors to Consider When Selecting Connector Cables for Industrial Use

When you're picking out connector cables for industrial stuff, there are a few key things you really want to keep in mind to make sure everything works smoothly and stays reliable. First off, think about the environment where these connectors will be used. I mean, according to a 2022 report by the IEC, more than 30% of equipment failures in factories and industrial sites happen because the cables weren’t suited for the conditions—like temperature swings, moisture, or exposure to chemicals. So, choosing cables that are rated for those specific conditions can save you a lot of headaches down the line.

When you're picking out connector cables for industrial stuff, there are a few key things you really want to keep in mind to make sure everything works smoothly and stays reliable. First off, think about the environment where these connectors will be used. I mean, according to a 2022 report by the IEC, more than 30% of equipment failures in factories and industrial sites happen because the cables weren’t suited for the conditions—like temperature swings, moisture, or exposure to chemicals. So, choosing cables that are rated for those specific conditions can save you a lot of headaches down the line.

And don’t forget about the electrical needs of your application. The ANSI points out that mismatched cable specs can cause inefficiencies and pose safety risks. In fact, about 15% of industrial machine breakdowns are linked to poor electrical connections. It’s super important to look at things like voltage ratings, how much current the cable can handle, and whether you need shielding. By sticking to these standards and making sure your cables match up with your existing systems, you’re setting yourself up for longer-lasting equipment, better performance, and, in the end, saving some cash while boosting productivity.

Comparative Analysis of Popular Connector Cable Types and Their Limitations

When you're choosing connector cables for industrial setups, it’s super important to get a good handle on the different types out there and what they can or can't do. You’ll often come across circular connectors, rectangular ones, and modular types — each tailored for specific tasks. For example, circular connectors are pretty much the go-to when you need something tough that can handle harsh environments; they’re sturdy and built to resist weather and other challenging conditions. On the flip side, rectangular connectors are great if you’re working in tight spots where space is limited, since they pack a lot into a smaller area. Modular connectors are also pretty flexible—they let you swap out parts and make changes easily. But hey, they can get a bit complicated, and if they’re not maintained well, reliability might suffer.

A quick tip: Always think about where your cables will be running. If you’re in a high-vibration zone, circular connectors might give you better stability. But if your project keeps changing and you need to reconfigure things often, modular options can really come in handy.

At Yueqing Xulian Electronics Co., Ltd., we’re all about creating top-quality connectors for cars and industrial use. With years of experience in design and manufacturing, we make sure our products work reliably no matter the setting. We've got the expertise and the resources to meet pretty much any customer need.

Another tip: Make sure to regularly check and clean your connector cables. Taking a little time to care for them can seriously extend their lifespan and help you avoid those inconvenient failures when you least expect them.

Best Practices for Maintaining and Troubleshooting Connector Cables

Taking care of and troubleshooting connector cables in industrial environments isn't just a good idea—it’s pretty much essential to keep everything running smoothly and last longer. Doing regular checks can really save you from unexpected failures down the line. So, it’s worth peeking at those cables—look out for frayed wires, loose connections, or any signs of wear and tear that might pop up. Catching these early means you can replace the cable before it causes a big headache.

Here’s a quick tip: keep some spare cables lying around. Trust me, it makes a huge difference. When something goes wrong, being able to swap out a faulty cable on the spot means less downtime and fewer headaches trying to track down the issue.

And, if your system starts acting up, a good first step is to check how the connectors are aligned. Sometimes, if they’re not seated just right, you’ll get those annoying intermittent connections that lead to errors. Make sure everything’s snug and locked in. Also, a quick clean with a specialized electronic cleaner can do wonders—dirt or corrosion can sneak in and mess with performance.

Oh, and another handy tip: use labels or color coding for your cables. It might seem simple, but it really helps when you’re troubleshooting. You’ll spend less time hunting for the culprit and more time actually fixing what’s wrong, which keeps your operation humming along without a hitch.

Connector Cable Usage in Various Industries

Optimizing Performance and Safety: The Essential Role of SCHUTZKAPPE F4+7P Cable Accessories in Modern Connectors

In the modern landscape of electrical connectors, optimizing performance and safety is more crucial than ever. The SCHUTZKAPPE F4+7P cable accessories stand out as essential components that enhance the reliability and efficiency of connections. These round DIN flip connector tail covers are designed meticulously to provide not just protection but also to ensure seamless connectivity in various applications. By utilizing advanced materials and innovative designs, these accessories significantly reduce the risks of malfunction and promote longer service life.

Our commitment to quality is reinforced by a comprehensive quality control process. We employ a wide range of testing instruments to ensure that every product meets stringent standards. Furthermore, our professional technical team, backed by ISO 9001 and IATF16949 management system certifications, ensures that every aspect of the product's design and implementation is optimized for superior performance. We take pride in our fast delivery times and excellent after-sale service, making us a trusted partner for businesses looking to enhance their connector systems. The SCHUTZKAPPE F4+7P cable accessories are indeed vital tools in achieving optimal performance and safety in modern electrical connections.

FAQS

: Connector cables are essential for transmitting power and data between machinery, ensuring systems operate smoothly and efficiently.

A poor choice of connector cable can lead to signal loss, increased downtime, and even equipment damage.

It is important to consider factors such as extreme temperatures, moisture, and corrosive substances to choose cables that are rated for these conditions.

The length of the cable can affect signal quality, as longer cables may lead to signal degradation.

Thicker cables provide better conductivity but may sacrifice flexibility, so it is important to balance these factors based on application needs.

Secure locking mechanisms help prevent accidental disconnections during operation, ensuring continuous functionality.

Key electrical requirements include voltage rating, current carrying capacity, and shielding requirements to ensure safety and efficiency.

More than 30% of equipment failures can be attributed to improper cable selection due to environmental influences, leading to increased chances of failure.

Adhering to standards set by organizations such as the American National Standards Institute (ANSI) ensures compatibility and enhances the longevity and performance of equipment.

Mismatched specifications can lead to inefficiencies and safety hazards, contributing to approximately 15% of industrial machinery failures.

Conclusion

In today’s industrial world, picking the right connector cable isn’t just a technical detail — it’s a big deal for keeping things running smoothly and reliably. Knowing why connector cables matter across different applications can really help businesses dodge those annoying issues like dropped signals or connection hiccups. When you’re choosing cables, it’s a good idea to think about things like the environment they'll be used in, whether they’re compatible with your equipment, and the specific performance specs you need. It’s all about making sure you get the right fit for your unique industrial setup.

Also, taking a look at the main types of connector cables out there and understanding their limitations can really help you make smarter choices. And don’t forget—regular maintenance and quick troubleshooting can seriously extend the life of your cables and keep things working smoothly. Here at Yueqing Xulian Electronics Co., Ltd., we’ve got a wide selection of top-notch connectors and accessories, including automotive and ECU connectors, all designed to meet your industrial needs and keep your operations running at their best.

Related Posts

-

10 Essential Tips for Choosing the Best Wire Cable Connectors

-

Comparing the Top 5 Best Waterproof Wire Connectors: Which One Reigns Supreme?

-

Exploring the Growth of Auto Car Accessories at the 137th Canton Fair 2025 in Guangzhou

-

Maximize Your Business Potential: Discover the Surge in Global Buyers at the 137th Canton Fair

-

How to Identify Quality Manufacturers for Optimal Automotive Wire Connectors

-

2025年最佳多插针连接器行业趋势与五大创新解析

Blog Tags: