10 Essential Tips for Understanding Electrical Connector Types Chart

Table of Contents

- Understanding Electrical Connectors: A Comprehensive Overview of Types

- Key Specifications: Amperage, Voltage, and Temperature Ratings Explained

- Identifying Connector Types: From Headers to Molex and Beyond

- The Importance of Compatibility: Matching Connectors with Applications

- Durability Matters: Selecting Connectors Based on Environmental Conditions

- Trends in Connector Technology: Innovations Enhancing Performance and Safety

- Maximizing Efficiency: Insights from Industry Reports on the Timer Connector System Series and Its Impact on Operations

- FAQS

- Conclusion

- Related Posts

Getting a good grip on the different kinds of electrical connectors is pretty important if you’re working with electronics, automotive stuff, or putting together wiring harnesses. In this post, I want to walk you through the 'Electrical Connector Types Chart' — you know, that handy guide that breaks down the various connector types, what they’re used for, features, and specs. As a company that’s been around the block a few times, Yueqing Xulian Electronics Co., Ltd. is all about high-quality automotive connectors, ECU connectors, terminals, wiring harnesses, and all that good stuff. We’re always pushing forward with research and innovation, so hopefully, our insights help you make sense of the sometimes confusing world of electrical connectors. The more you understand the different types and tips out there, the better you’ll be at picking the right parts for your projects — making sure everything runs smoothly and reliably in the end.

Understanding Electrical Connectors: A Comprehensive Overview of Types

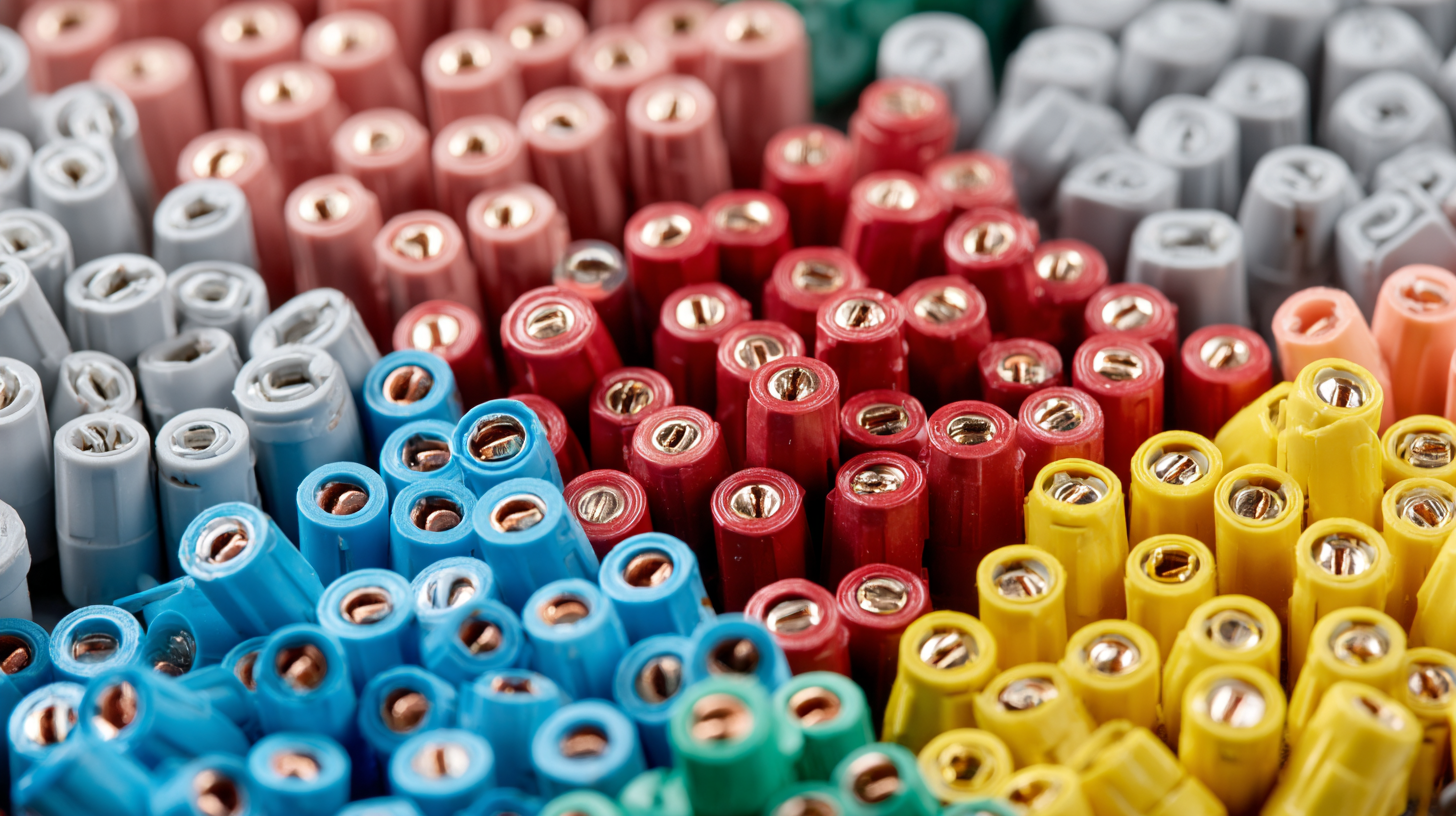

Electrical connectors might not be the most glamorous part of your project, but trust me, they’re super important when it comes to keeping everything working smoothly. There’s actually quite a few different types out there, and knowing which one to grab can save you a lot of headaches. From simple wire-to-wire connectors to the more complex multi-pin ones, each has its own purpose. For example, brands like Molex and JST are pretty common in consumer gadgets—they’re small and easy enough for anyone to handle. On the flip side, bigger connectors like the Anderson Powerpole are used where you need to handle higher currents. If you take a quick look at a connector chart, it’ll help you figure out which one fits your project best—kind of like a cheat sheet.

But it’s not just about the size or shape. You also wanna pay attention to things like voltage limits, how much current they can handle, and whether they can stand up to tough environments. Some connectors are built to handle rain and dust, making them perfect for outdoor or harsh conditions. Plus, the materials used—plastic or metal—really impact how long they last and how well they perform over time. Whether you’re a pro or just tinkering around as a hobbyist, knowing these details will help you make smarter choices. In the end, it’s all about picking the right connector for the job, so everything stays safe and works like a charm.

Key Specifications: Amperage, Voltage, and Temperature Ratings Explained

Getting a solid grasp on the specs of electrical connectors is pretty important if you want to pick the right one for your project. Things like amperage, voltage, and temperature ratings aren’t just technical mumbo jumbo – they actually decide how well your connections work and how safe they are. For example, amperage is all about how much current the connector can handle without overheating; pushing past that limit? Not a good idea, since it could lead to failures or even fires. So, when you’re choosing a connector, make sure its amperage rating matches what your circuit needs to keep everything running smoothly.

As for voltage ratings, they tell you the maximum voltage the connector can handle safely. Use one with a too-low rating, and you risk electrical sparks or harming your components. It’s especially important to think about where and how you’re using it — high-voltage stuff needs sturdy, reliable connectors. Then there’s temperature ratings, which are all about whether the connector can handle heat without falling apart. If you’re working in hot environments, you’ll want to pick connectors with good thermal resistance to avoid issues down the line. Basically, understanding these specs helps you make smarter choices, which means your system will perform better and last longer — no surprises or shortcuts needed.

Identifying Connector Types: From Headers to Molex and Beyond

When you're diving into the world of electrical connectors, it’s pretty important to get a good grasp of the different types out there, whether you're just a hobbyist or a pro. The variety is actually quite wide—ranging from simple headers to more complex options like Molex connectors. Headers, those straightforward pin-and-socket things, are often used in slim, low-profile gadgets. They come in all sorts of configurations, which makes them super versatile depending on what you need. Figuring out the right header for your project can really boost how smoothly your connections work.

Now, moving on to Molex connectors—they're honestly some of the most common choices when it comes to powering up your devices. Renowned for being pretty reliable, these connectors come in all sorts of sizes and styles, so you can find one that suits just about any application. Knowing what makes Molex connectors tick—like their locking mechanisms and how they connect to the board—can really make a difference in choosing the best fit for your project. So yeah, understanding the differences between these types isn’t just about picking the right connector; it’s really about making your overall electronic setup perform better and last longer.

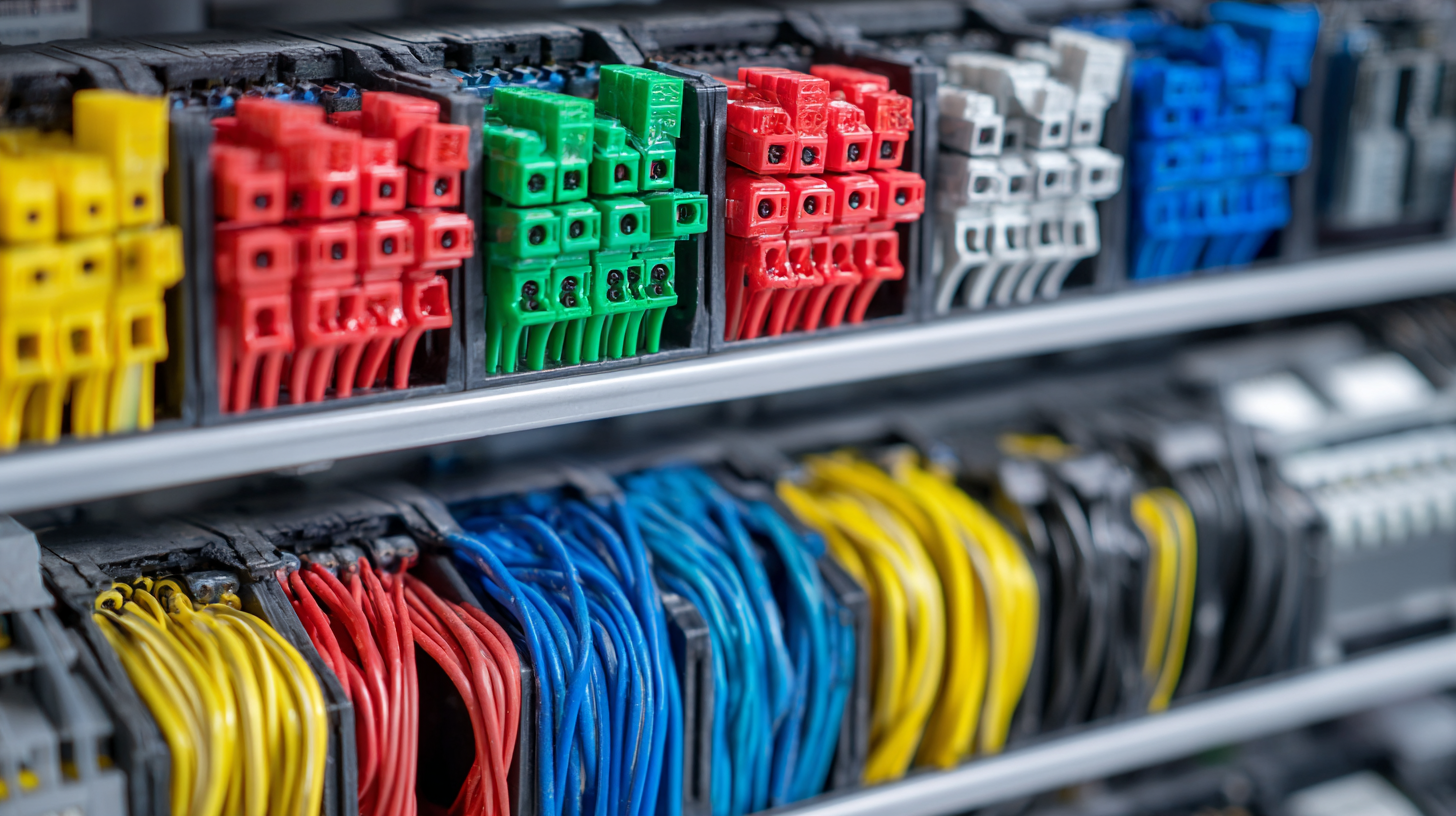

The Importance of Compatibility: Matching Connectors with Applications

Getting a good grip on how electrical connectors fit with their specific uses is pretty important these days. Have you seen industry reports? They’re saying the worldwide market for electrical connectors could hit around $72 billion by 2026! That’s mainly because more and more gadgets and systems need to stay connected. This really shows why it’s so crucial to pick the right connector for the job—if you don’t, you risk things failing or not performing as well as they should.

Take discrete graphics cards, for example—they make up nearly 60% of the overall graphics card market. These usually need special connectors that are built for high-performance stuff like gaming or server data processing. If the connector isn’t the right one, it can drag down hardware efficiency and even impact system security—especially as tech gets more complex. With new trends like AI-powered PCs coming into play, making sure you have the right electrical connectors isn’t just a nice-to-have; it’s essential. Manufacturers and tech folks need to really pay attention to compatibility to keep everything running smoothly and safely.

Durability Matters: Selecting Connectors Based on Environmental Conditions

Choosing the right electrical connectors isn't just about functionality — durability is a big deal, especially when you think about the kinds of environments they'll be working in. Take the hydraulic fluid connectors market in North America, for example — it's expected to grow quite a bit. That means we’ll need connectors that can really handle the tough conditions out there. By around 2033, not only will this market be larger, but the connectors themselves will need to stand up to all sorts of pressures and temperature swings.

On top of that, tech advances are shaking things up, especially in areas like 6G networking. Those high-tech RF connectors are pretty much essential if we want these networks to succeed, and they come with their own set of challenges — like surviving extreme weather and other harsh conditions. As the industry gears up to create more rugged, smaller, and more efficient solutions, it’s super important for engineers and designers to really get what makes a connector durable.

With trends leaning toward more sustainable, high-performance options, understanding the ins and outs of different connector types and how well they adapt to different environments is more important than ever in today’s fast-changing market.

Trends in Connector Technology: Innovations Enhancing Performance and Safety

You know, the way electrical connector tech has been evolving is really opening up new doors for better performance and safety in all sorts of applications. Lately, especially in the automotive world, there's been a real boom, and the market’s growing rapidly. Charting the course from about USD 8 billion in 2025, it’s expected to hit around USD 13.33 billion by 2033 — that’s a solid compound annual growth of 6.6%. Most of this surge is due to how more and more vehicles are being electrified, plus the increasing complexity of their electrical systems, which kind of calls for more reliable, efficient connectors that truly do the job.

On top of that, smart accessories are making a big difference by boosting the reliability of electrical grids. These tech innovations not only keep modern networks running smoothly but also play a crucial role in making electric vehicles safer and more functional. For instance, developing high-performance connectors that can handle the demands of EV technology is a big deal because they’re basically the crucial links that help with charging and managing energy seamlessly. We’re also seeing exciting stuff like pyrotechnic circuit breakers built for high-voltage setups, which really highlights how safety features are evolving in connector designs. As everything heads towards more sustainability and efficiency, it’s clear that integrating these advanced connector technologies is going to be more and more important to meet what’s coming next.

10 Essential Tips for Understanding Electrical Connector Types Chart - Trends in Connector Technology: Innovations Enhancing Performance and Safety

| Connector Type | Usage | Material | Max Voltage Rating | Innovations |

|---|---|---|---|---|

| Circular Connector | Industrial Machines | Aluminum | 500V | Waterproofing Technology |

| Rectangular Connector | Telecommunications | Plastic | 300V | Signal Integrity Enhancements |

| USB Connector | Consumer Electronics | Copper | 5V | Fast Charging Capability |

| RJ45 Connector | Networking | Plastic | 48V | PoE (Power over Ethernet) |

| HDR Connector | Automotive | Stainless Steel | 700V | High Temperature Resistance |

Maximizing Efficiency: Insights from Industry Reports on the Timer Connector System Series and Its Impact on Operations

In today's competitive landscape, maximizing efficiency is crucial for operational success, particularly when it comes to implementing reliable systems like the Timer Connector System Series. Industry reports highlight how this innovative solution enhances productivity through its robust design and seamless integration capabilities. By ensuring an efficient flow of operations, businesses can significantly reduce downtime and improve overall performance.

At our company, we recognize the importance of quality and reliability. We utilize a comprehensive range of testing instruments to guarantee that our products, including the PCB mount header with its vertical design, meet rigorous standards. Our professional technical team, certified under ISO 9001 and IATF16949 management systems, is dedicated to ongoing improvement and innovation. This commitment not only translates to superior product quality but also ensures that our clients receive timely delivery and exceptional after-sale support.

The Timer Connector System Series stands out in applications where space and efficiency are paramount. Its thoughtfully designed connection interface facilitates straightforward assembly, making it ideal for a variety of uses in electronics. Embracing such technologically advanced solutions empowers businesses to streamline their operations and achieve significant gains in productivity.

FAQS

: Electrical connectors are devices that join electrical circuits together, ensuring reliable connections within electrical systems. They are crucial for the performance and safety of electrical installations.

Common types of electrical connectors include wire-to-wire connectors, Molex connectors, JST connectors, Anderson Powerpole connectors, and headers. Each type is designed for specific applications based on size, capacity, and use cases.

To choose the right electrical connector, consider factors such as voltage rating, current capacity, environmental resistance, and the specific requirements of your project. Familiarizing yourself with a connector types chart can aid in selection.

When selecting connectors for harsh environments, look for properties such as waterproof or dustproof features, durability against varying pressures and temperatures, and materials that enhance longevity.

Durability is significant because connectors used in demanding conditions must withstand environmental stressors without compromising performance. Resilient connectors improve reliability and safety.

Molex connectors are known for their reliability in power delivery, coming in various sizes and orientations. They also offer unique features like locking mechanisms and wire-to-board capabilities, making them suitable for a wide range of devices.

Recent trends influencing connector design include advancements in technology like 6G networking, the demand for ruggedized and miniaturized solutions, and a greater focus on sustainability and enhanced performance.

Understanding connector types is essential because it helps in optimizing performance, enhancing efficiency, and ensuring safety in electrical designs, leading to better decision-making in installations.

Conclusion

Getting a solid grip on electrical connectors is pretty important if you're aiming for top-notch performance in whatever project you're working on. That 'Electrical Connector Types Chart' is actually a handy tool—it's like your go-to guide, showing you all kinds of connector types, from headers to Molex connectors and more. When you're picking out the right connector, don’t forget to check out key specs like maximum amperage, voltage, and temperature ratings. These little details really make a difference in how well it works with your setup.

Durability’s also a big deal because environmental stuff—like moisture or vibrations—can seriously mess with how connectors hold up. Staying in the loop about new trends in connector tech can be a game-changer, leading to safer and more efficient solutions. Here at Yueqing Xulian Electronics, we’re proud to provide high-quality automotive connectors, ECU connectors, and wiring harnesses that tick all these boxes—trust us, reliability and performance are what we're all about in every product we make.

Related Posts

-

Unlocking the Advantages of Top Electrical Connector Types for Your Projects

-

Global Solutions in Electrical Connectors Shaping the Future of Connectivity

-

Maximize Your Business Potential: Discover the Surge in Global Buyers at the 137th Canton Fair

-

Top 10 Electrical Box Connector Manufacturers from China at the 137th Canton Fair

-

How to Choose the Best Male Female Wire Connectors for Your Projects

-

Innovative Electrical Cable Connectors Trends for 2025 and Their Advantages for Global Buyers

Blog Tags: