10 Essential Tips for Choosing the Right Battery Connector: Boost Performance by 30%!

Table of Contents

- Understanding Different Types of Battery Connectors for Optimal Performance

- Identifying Key Factors That Impact Connector Efficiency

- Evaluating Material Choices: Copper vs. Aluminum for Battery Connectors

- Importance of Proper Sizing: How to Match Connectors to Your Battery's Needs

- Common Mistakes to Avoid When Selecting Battery Connectors

- Testing and Maintenance: Ensuring Long-Term Performance of Connectors

- FAQS

- Conclusion

- Related Posts

In today's fast-moving world of electronics, choosing the right battery connector really can’t be overlooked. A good, well-designed connector isn’t just about safety and reliability; it can actually boost your system’s performance by up to 30%, at least that's what recent studies in automotive electronics suggest. And if you’ve been paying attention, you’ll notice that demand for advanced connectors in the car industry is on the rise — mainly because more people are jumping on the electric and hybrid vehicle bandwagon. These cars need sturdy, efficient connectors to handle bigger power needs and keep everything running smoothly.

Understanding Different Types of Battery Connectors for Optimal Performance

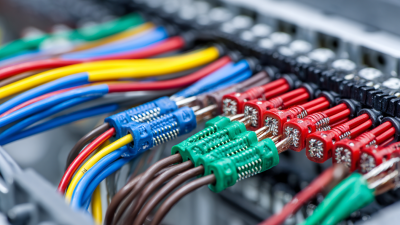

When selecting the right battery connector, understanding the various types available is crucial for achieving optimal performance.

Battery connectors come in several forms, including

spade connectors, ring terminals, and

bullet connectors. Each type serves a specific purpose and offers different benefits

depending on the application. For instance, spade connectors are versatile and allow for quick disconnection, making them ideal for

tools or equipment that require regular maintenance. On the other hand, ring terminals provide a secure connection that is less likely

to loosen over time, which is essential for applications with high vibrations, such as automotive or aerospace sectors.

Additionally, material composition and design play a significant role in the performance of battery connectors. Copper connectors are

widely preferred for their excellent conductivity and durability, while

gold-plated options offer superior resistance to corrosion and ensure a reliable connection

even in harsh environments. It's also important to consider the connector's size and compatibility with your battery system.

Choosing an appropriately rated connector not only enhances performance but also ensures safety, preventing overheating and

potential failure. By understanding these different types of battery connectors, you can make an informed choice that boosts

performance significantly.

Identifying Key Factors That Impact Connector Efficiency

Choosing the right battery connector is crucial for enhancing the performance and efficiency of any electronic system. Factors such as material composition, contact resistance, and environmental resistance significantly impact connector performance. According to a report by the Electronics Industry Association, connectors that exhibit low contact resistance can improve overall system efficiency by up to 30%. This is particularly relevant in automotive applications, where minimal energy loss is paramount for performance and safety.

Tip: Opt for connectors made from high-conductivity materials, such as copper alloy, to ensure lower resistance and better performance.

At Yueqing Xulian Electronics Co., Ltd., we specialize in providing a range of battery connectors designed for high efficiency and reliability. Our automotive connectors and ECU connectors are engineered to meet stringent industry standards, ensuring robust connections that withstand harsh conditions. Another important factor is the connector’s insulation material, which should protect against environmental factors like moisture and temperature variations.

Tip: Choose connectors with superior insulation materials, such as silicone or PTFE, to enhance durability in challenging environments.

Incorporating these essential tips can lead to enhanced connector efficiency, ultimately boosting overall system performance. With our expertise in manufacturing and R&D, Xulian strives to offer products that not only meet the demands of modern technology but also push the boundaries of performance.

Battery Connector Efficiency Comparison

Evaluating Material Choices: Copper vs. Aluminum for Battery Connectors

When it comes to battery connectors, the material choice can significantly impact overall performance. Copper and aluminum are the two primary options on the market, each with its distinct advantages. Copper connectors, for instance, offer superior conductivity, ensuring minimal energy loss and maximizing performance. On the other hand, aluminum connectors are lighter and often more cost-effective, making them an attractive choice for various applications. Ultimately, the decision should reflect the specific requirements of your electrical system.

To boost the performance of your battery connectors by up to 30%, consider the following tips:

- Match the connector material with the application environment. For high-current applications, copper may be the optimal choice due to its lower resistance.

- Ensure proper surface treatment to prevent corrosion, which can degrade performance over time.

- Prioritize quality over cost—investing in high-grade connectors will pay off in reliability and efficiency.

Understanding the properties of copper and aluminum can help you make informed decisions. While copper connectors shine in high-performance scenarios, aluminum can serve well in situations where weight and cost are critical. Ultimately, the right choice hinges on balancing conductivity, durability, and application-specific needs.

Importance of Proper Sizing: How to Match Connectors to Your Battery's Needs

Choosing the right battery connector is crucial for optimizing performance and ensuring safety. Proper sizing is a key aspect that cannot be overlooked. According to a report by the Electric Power Research Institute (EPRI), mismatched connectors can lead to a loss of up to 20% in performance due to increased resistance and energy loss. This highlights the importance of matching connectors to the specific needs of your battery system.

When selecting connectors, first assess the current and voltage requirements of your battery. Ensure that the connector can handle the maximum current draw without overheating. For instance, a recent study indicated that using connectors designed for higher ampacity can enhance efficiency and reduce energy waste by approximately 30%. Consider utilizing connections that offer adequate cross-sectional area to minimize resistive losses.

Additionally, don’t underestimate the environmental factors that may impact connector performance. For outdoor applications, utilize connectors with appropriate weatherproof ratings. As per industry guidelines, connectors rated for IP67 or higher are ideal for protecting against dust and water ingress, further preserving battery life and optimizing performance. By implementing these tips, you can ensure that your battery connections not only meet but exceed performance expectations.

10 Essential Tips for Choosing the Right Battery Connector: Boost Performance by 30%!

| Tip Number | Tip Description | Importance | Recommended Size |

|---|---|---|---|

| 1 | Choose connectors with a compatible voltage rating. | Ensures safety and efficiency. | Rated voltage should match or exceed the battery voltage |

| 2 | Select connectors based on current-carrying capacity. | Prevents overheating and damage. | Ensure connector rating is greater than max current draw |

| 3 | Consider environmental factors such as moisture and temperature. | Longer lifespan and reliable function in varying conditions. | Select weatherproof connectors for outdoor use |

| 4 | Ensure ease of installation and removal. | Reduces downtime and increases user convenience. | Choose connectors with ergonomic designs |

| 5 | Check for compatibility with different battery chemistries. | Avoids risks of improper charging. | Evaluate connectors based on Li-ion, NiMH, or lead-acid |

| 6 | Use connectors with reliable locking mechanisms. | Prevents accidental disconnection. | Look for connectors with click-lock features |

| 7 | Evaluate the material of the connectors. | Materials affect durability and conductivity. | Copper or gold-plated connectors are recommended |

| 8 | Examine the contact surface area. | Larger contact areas improve current flow. | Select connectors with substantial contact points |

| 9 | Look for connectors with strain relief features. | Ensures a secure fit and reduces stress on cables. | Find connectors with integrated strain relief |

| 10 | Research user reviews and specifications. | Helps in making informed decisions. | Select from connectors with positive feedback |

Common Mistakes to Avoid When Selecting Battery Connectors

When selecting battery connectors, it's crucial to avoid some common mistakes that can lead to decreased performance and potential damage. One common error is overlooking the compatibility between connectors and battery types. Using a connector that isn't rated for the specific voltage and current can result in overheating or even failure. Moreover, neglecting to consider the gauge of the wire used in the connectors can significantly impact efficiency. Thinner wires may not handle higher currents well, which can cause resistance and energy loss.

Another frequent mistake is failing to account for environmental factors. For example, connectors exposed to moisture or extreme temperatures can corrode or malfunction. It’s vital to choose connectors that are designed for the conditions they will face. Additionally, many people tend to leave devices plugged in for extended periods, as seen in smartphone charging habits. This practice might not directly involve battery connectors, but it highlights the importance of ensuring all components are suitable for prolonged use. By being mindful of these common pitfalls, you can enhance battery performance and longevity significantly.

Testing and Maintenance: Ensuring Long-Term Performance of Connectors

When it comes to battery connectors, ensuring long-term performance is crucial for maximizing efficiency and reliability. Regular testing and maintenance not only extend the life of your connectors but can also enhance performance by as much as 30%, based on industry studies. According to a report by the International Energy Agency, poorly maintained connectors can lead to energy losses upwards of 15%, underscoring the importance of proper oversight.

One essential tip for maintaining battery connectors is to perform regular visual inspections. Look for signs of corrosion, wear, or any physical damage that could hinder performance. Another key practice is to ensure tight connections. A study published in the Journal of Power Sources highlights that a snug fit leads to better conductivity and reduced resistance, further boosting efficiency.

Incorporating maintenance practices such as cleaning the contact points regularly with isopropyl alcohol can minimize oxidation and improve overall connectivity. Additionally, using appropriate connector types designed for your specific application can prevent overheating and material degradation. By adopting these maintenance habits and following established tips for proper connector selection, you can significantly improve your battery system's performance and longevity.

FAQS

: The main types of battery connectors include spade connectors, ring terminals, and bullet connectors, each serving specific purposes and offering various benefits depending on the application.

Spade connectors are versatile and allow for quick disconnection, making them suitable for tools or equipment needing regular maintenance, while ring terminals provide a more secure connection, ideal for high-vibration applications like automotive or aerospace.

Copper connectors are preferred for their excellent conductivity and durability, whereas gold-plated connectors offer superior corrosion resistance for reliable connections in harsh environments.

Proper sizing is crucial because mismatched connectors can lead to a performance loss of up to 20% due to increased resistance and energy loss, making it essential to match connectors to the specific needs of your battery system.

Assess the current and voltage needs of your battery and choose connectors designed for the maximum current draw to avoid overheating and inefficiency.

For outdoor applications, connectors with a weatherproof rating of IP67 or higher are recommended to protect against dust and water ingress.

Using connectors designed for higher ampacity can enhance efficiency and reduce energy waste by approximately 30%, leading to better overall performance.

Look for connectors that offer an adequate cross-sectional area to minimize resistive losses, which enhances energy efficiency and safety.

The choice of material directly impacts conductivity, durability, and corrosion resistance, influencing the reliability of the connection and overall battery performance.

Using an incompatible or improperly rated connector can lead to overheating, potential failure, and reduced battery life, impacting both performance and safety.

Conclusion

In today's high-tech landscape, selecting the right battery connector is crucial for boosting performance by up to 30%. Understanding the different types of battery connectors available can significantly influence efficiency and longevity. Key factors such as material choice—copper versus aluminum—play an important role in connector effectiveness. Additionally, proper sizing ensures that the connectors meet battery needs without compromising performance.

It's also vital to recognize common mistakes that can lead to suboptimal selections, and to implement a routine for testing and maintenance to sustain connector performance over time. Yueqing Xulian Electronics Co., Ltd. specializes in manufacturing a range of automotive connectors and accessories, providing reliable solutions that align with the best practices in battery connector selection for maximum performance.

Related Posts

-

Why Battery Connectors Are Essential for Modern Electronics and Power Solutions

-

Understanding Car Battery Connectors: Essential Tips for Safe and Efficient Usage

-

Understanding the Impact of Battery Connectors on Modern Technology Efficiency

-

Unlocking Efficiency: Benefits of Advanced Automotive Wiring Harness Solutions

-

Elevate Your Automotive Standards: Discover China's Premium Wiring Harnesses for Global Markets

-

7 Essential Tips for Choosing the Best 6 Pin Connector for Your Projects