The Comprehensive Handbook for Understanding Electrical Terminal Connectors

Table of Contents

- Understanding the Basics: What Are Electrical Terminal Connectors?

- Types of Electrical Terminal Connectors and Their Applications

- Selecting the Right Connector for Your Project Needs

- Step-by-Step Guide: How to Install Electrical Terminal Connectors

- Common Mistakes to Avoid When Using Electrical Terminal Connectors

- Maintenance Tips for Ensuring Longevity of Terminal Connectors

- Exploring the Evolution of Precision Engineering: Insights from the Latest Market Reports on 0.6MM Series Products

- FAQS

- Conclusion

- Related Posts

In today’s lightning-fast tech world, getting a handle on Electrical Terminal Connectors is pretty important if you want your electrical systems to run smoothly and reliably across different industries. I read recently that the global connector market is expected to hit around $90 billion by 2025 — crazy, right? A big part of that boom comes from the rising need for better connectivity solutions, especially in cars and electronics. Yueqing Xulian Electronics Co., Ltd. is really aware of how big this market is becoming. They’re using their know-how in manufacturing and R&D to create top-notch automotive connectors, ECU connectors, terminals, wiring harnesses, and a bunch of other accessories.

As we look into some of the common issues that come up with Electrical Terminal Connectors, it’s super important to understand how these problems can affect performance and safety — whether you’re a manufacturer or an engineer, knowing this stuff is key to staying ahead.

Understanding the Basics: What Are Electrical Terminal Connectors?

Electrical terminal connectors might not be the coolest topic ever, but trust me, they’re pretty important, especially when it comes to cars. These tiny connectors act like the middlemen between wires, making sure electricity flows smoothly. And with car tech evolving so quickly—more complex electronics, better features—it's crucial to get a good grip on these connectors. If you’re into automotive stuff, you’ll want connectors that can handle the heat, the vibrations, and all that rough road. Pay attention to things like how much current they can handle and how well they resist contact resistance—that stuff really matters for keeping things running reliably.

Oh, and a quick tip: knowing the basics of wiring is super helpful here. When you're putting together a wiring harness, it usually makes sense to connect things logically—starting from the main panel, then heading out to the gadgets like the dashboard, headlights, turn signals, you know the drill. Doing it carefully and correctly means fewer mistakes and fewer headaches down the road.

And don’t forget—make sure all your connections are tight and free from corrosion. It’s worth checking your wiring and connectors now and then, just to catch any wear and tear early. Trust me, a little upkeep can save you a lot of trouble later on.

The Comprehensive Handbook for Understanding Electrical Terminal Connectors

| Connector Type | Material | Current Rating (A) | Voltage Rating (V) | Common Applications |

|---|---|---|---|---|

| Fork Terminal | Copper, Nickel Plated | 15 | 600 | Automotive, HVAC systems |

| Ring Terminal | Copper, Tin Plated | 20 | 250 | Electrical panels, Battery connections |

| Butt Connector | Copper | 30 | 600 | Wire splicing, Electrical repair |

| Spade Terminal | Copper, Tin Plated | 25 | 300 | Home appliances, Industrial machinery |

| Bullet Connector | Aluminum, Nickel Plated | 10 | 125 | Lighting systems, Circuit boards |

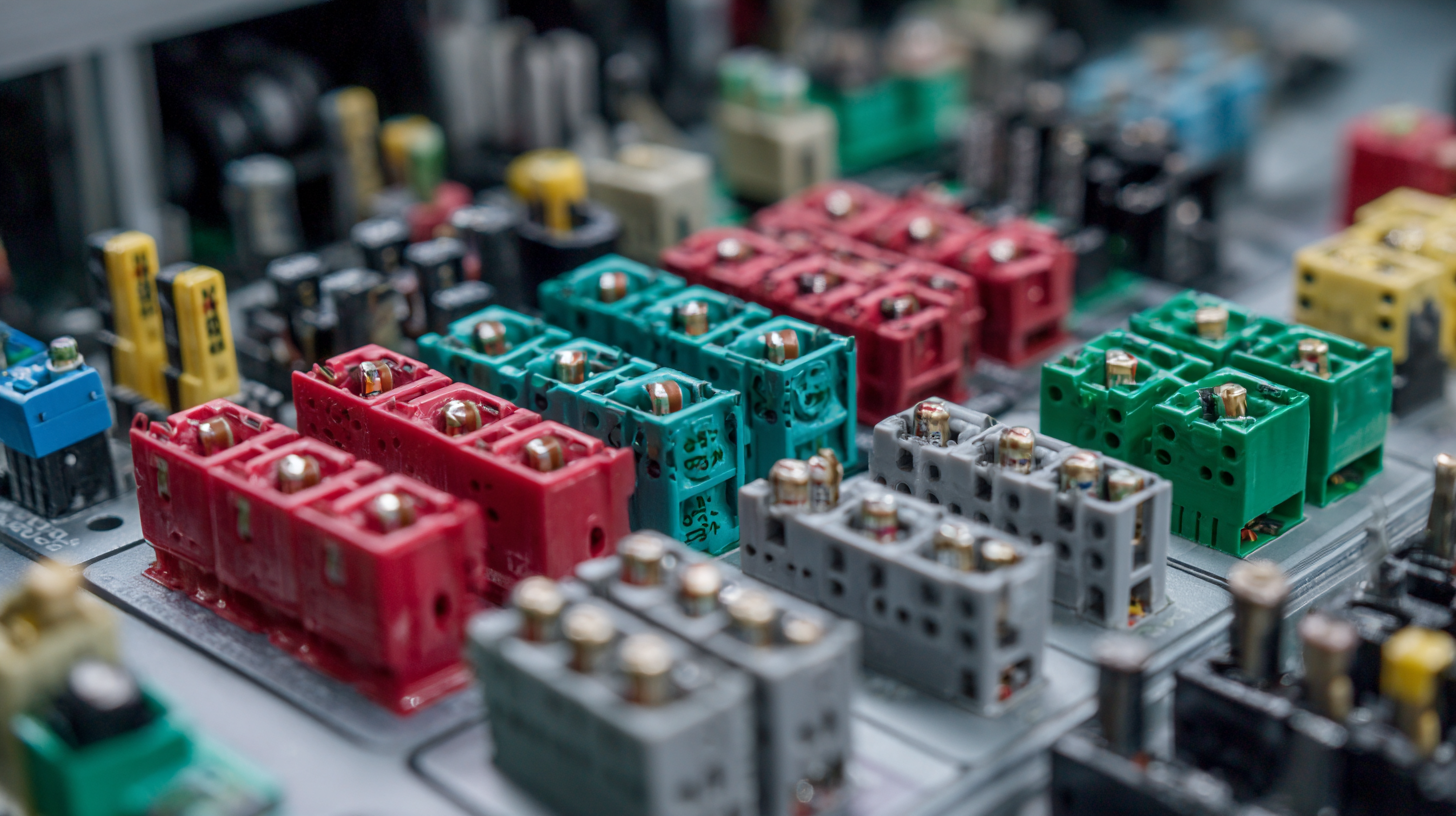

Types of Electrical Terminal Connectors and Their Applications

Hey, have you heard? The market for electrical terminal connectors is really heating up! It's expected to grow quite a bit, mainly because more and more industries are demanding them for all sorts of applications. As of 2023, the global connector market is sitting around $82.2 billion, and experts say it could hit about $141.1 billion by 2032. That's a pretty impressive annual growth rate of roughly 6.3% from 2024 onward. This surge makes sense when you consider how many digital gadgets we’re using nowadays, along with the more complex wiring systems popping up in both industrial setups and everyday consumer devices.

Now, if we talk about specific types of connectors, wire-to-board connectors are really showing some remarkable growth. Forecasts suggest that this segment will jump from roughly $7.8 billion in 2025 to over $15.2 billion by 2035. Their rise makes sense because they’re super important for creating reliable links between different circuit boards inside all our electronic gadgets. After all, they’re key to making sure signals and power move smoothly. On the other hand, the overall wire connector market isn’t lagging behind — it’s expected to grow at about 5.9% annually and could reach almost $95 billion by 2035. It just goes to show how vital these little connectors are in today’s tech-driven world.

Selecting the Right Connector for Your Project Needs

When you're trying to pick out the right electrical terminal connector for your project, there are a few key things you really want to keep in mind—things that match up with what you actually need. Honestly, with so many different types of connectors out there, it can get pretty overwhelming! You’ve gotta think about where you’re gonna use it, how much current it needs to handle, and how sturdy it needs to be. For example, if you’re dealing with automotive stuff, you’ll want something super durable that can handle tough conditions. On the other hand, ECU connectors need to be precise so that signals stay clear and reliable.

At Yueqing Xulian Electronics, we’re experts when it comes to making all sorts of connectors—whether it's for cars or ECUs—focused on delivering top-notch performance. We’re always researching and improving, so our products match what’s needed in different industries. When you understand what your project requires and work with us, choosing the right connector becomes way easier—and you can feel confident it’ll work safely and efficiently. Embrace good quality and innovation, and let our advanced solutions help take your electrical connections to the next level!

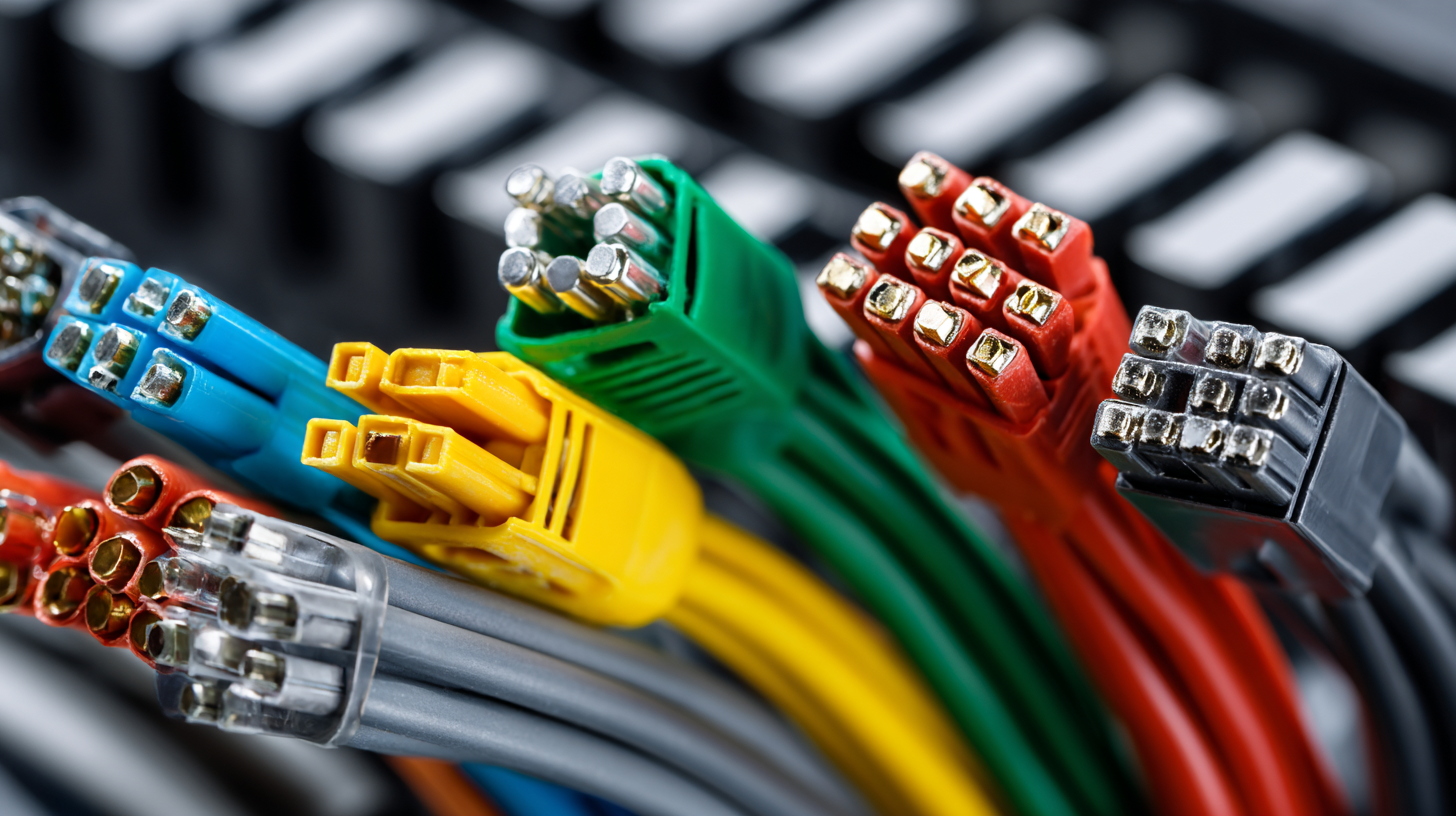

Step-by-Step Guide: How to Install Electrical Terminal Connectors

Installing electrical terminal connectors might seem a bit intimidating at first—trust me, I’ve been there! But honestly, once you break it down into simple steps, it’s totally doable. First off, make sure you’ve got the right tools ready—stuff like wire strippers, a good crimping tool, and don’t forget those safety gloves to keep your hands protected. So, start by prepping your wires: strip off some of the insulation so you’ve got enough bare copper to work with. Getting this part right is super important because it’ll prevent any weak spots that could cause issues down the line.

Next, pick the right terminal connector for your wire gauge and what you’re working on. Insert the stripped wire into the terminal, then squeeze it with your crimping tool—make sure you apply enough pressure to really secure it. A loose connection? No way—that could lead to electrical problems or even safety hazards. After you’ve done that, give everything a quick double-check—make sure all the connections are tight and properly insulated. Follow these steps, and you’ll be well on your way to doing a safe, solid install. Trust me, it’s pretty satisfying once you get the hang of it!

Common Mistakes to Avoid When Using Electrical Terminal Connectors

When you're working with electrical terminal connectors, avoiding some common mistakes can really make a difference in both safety and how well everything works. One thing a lot of folks mess up on is picking the wrong type of connector for their specific project. Using connectors that aren’t rated for the right voltage or current can cause them to overheat or even fail sooner than they should. So, it’s super important to always check the specs and make sure the connectors you choose can handle what your project demands.

Another mistake I’ve seen quite often is not stripping the wire insulation properly. Too much or not enough, and you’re asking for trouble. If you strip too much, the exposed wire might touch things it shouldn’t, which can cause a short circuit—definitely not something you want. On the flip side, if you don’t strip enough, the connection could be weak, leading to all kinds of weird, intermittent issues. Plus, make sure you push the wire all the way into the connector—half-hearted connections can cause arcing or poor contact down the line.

And don’t forget, securing your connections is a big deal. Skimping on tightening things up can lead to loose connections, which heat up and could even start a fire. So, always double-check that everything is snug and tight—using the right tools if needed. Paying attention to these little details can save you a ton of hassle, money, and make your setup safer overall.

Maintenance Tips for Ensuring Longevity of Terminal Connectors

When it comes to keeping your electrical terminal connectors in good shape, it's really important to understand what factors can affect their lifespan. I mean, according to a report from the IEEE, if you don’t maintain them properly, their life could be cut in half, which obviously isn’t great since it increases the chances of system failures. So, what’s the best way to keep them working smoothly? Well, regular check-ups and cleaning are key. Over time, dust, rust, and other gunk can build up, blocking the electrical connection and risking issues down the line.

But it's not just about cleaning; things like how tight you screw them in also matter a lot. The NEMA recommends following specific torque specs depending on the type and size of the connector. Overdoing it can cause cracks or stress, while not tightening enough might mean a shaky connection. Also, applying protective coatings and sealing things up properly helps guard against the elements—think moisture, temperature changes—that tend to speed up wearing out. If you follow these simple tips, you'll not only get better performance from your connectors but also extend their life way beyond what you might expect.

Exploring the Evolution of Precision Engineering: Insights from the Latest Market Reports on 0.6MM Series Products

In the ever-evolving landscape of precision engineering, the latest market reports on the 0.6MM series products provide invaluable insights into the trends and innovations shaping this dynamic field. This series exemplifies the increasing demand for precision and reliability in engineering applications, reflecting a commitment to quality that resonates throughout the industry.

Our KH1200043/KH1200043-20 type products embody this philosophy, backed by a professional technical team and a robust management system certified under ISO 9001 and IATF 16949. We leverage a wide array of testing instruments to ensure our products meet the highest standards, eliminating concerns about quality for our clients. Additionally, our commitment to fast delivery times and exceptional after-sale service positions us as a leader in the precision engineering sector, enabling customers to rely on us for their critical projects.

As we continue to explore the advancements in precision engineering, the 0.6MM series products not only meet current market demands but also pave the way for future innovations, demonstrating our proactive approach in adapting to industry shifts. With a strong emphasis on quality and efficiency, our products stand ready to cater to the evolving needs of the market, driving growth and excellence in precision engineering applications.

FAQS

: Electrical terminal connectors are components used for connecting electrical wires, essential for ensuring reliable electrical performance in various applications, especially in the automotive industry.

Selecting the right connector is crucial as it impacts the performance, durability, and functionality of electrical systems, particularly in environments with temperature fluctuations and vibrations, such as in vehicles.

Consider the application environment, current rating, contact resistance, and ensure the connectors are designed to withstand harsh conditions while providing optimal functionality.

Ensure that all connections are secure, free of corrosion, and regularly inspect wiring harnesses and connectors for wear and tear to enhance overall system reliability.

The assembly typically follows a logical order, starting from the main panel to the instruments, and then connecting to other components like headlights and turn signals.

Key factors include the application environment, required current rating, mechanical stability, and specific project needs, which influence the selection of suitable connector types.

Yueqing Xulian Electronics specializes in providing a diverse range of electrical connectors, offering expertise to help align project specifications with the right products for efficiency and safety.

Recent trends focus on advanced designs and technologies that enhance functionality and durability, accommodating the increasing complexity of automotive electronics.

Regular inspection for corrosion, securing connections, and ensuring proper assembly techniques can significantly maintain and improve the performance of electrical connectors.

Precision ensures reliable signal transmission in ECU connectors, which is vital for the effective functioning of electronic control units in automotive applications.

Conclusion

Hey there! If you're diving into the world of electrical systems, you’ll definitely want to check out the 'Comprehensive Handbook for Understanding Electrical Terminal Connectors.' It's a great intro to these super important little components. The guide walks you through the different types of terminal connectors, where they’re best used, and even offers some handy tips on picking the right one for your project. Plus, it includes a step-by-step walkthrough on how to install them properly, points out common mistakes to avoid, and shares some maintenance tricks to keep everything working smoothly and last longer.

Now, as someone who’s been in the field, I can tell you that Yueqing Xulian Electronics Co., Ltd. really knows their stuff. They’re a major player when it comes to designing and manufacturing top-notch electrical connectors and wiring solutions. Especially in the automotive world, they put a lot of focus on making sure their connectors are reliable and high-quality. It just goes to show, understanding these little connectors is key to making sure your electrical connections are solid and dependable in all kinds of applications.

Related Posts

-

Maximize Your Business Potential: Discover the Surge in Global Buyers at the 137th Canton Fair

-

Global Solutions in Electrical Connectors Shaping the Future of Connectivity

-

Top 10 Electrical Box Connector Manufacturers from China at the 137th Canton Fair

-

Unlocking the Advantages of Top Electrical Connector Types for Your Projects

-

17 Unique Uses for the Best Wire Pins in Global Manufacturing

-

How to Choose the Best Male Female Wire Connectors for Your Projects

Blog Tags: