Why Do Cable Terminals Matter for Your Electrical Connections?

Table of Contents

- The Importance of Cable Terminals in Electrical Systems

- Understanding Different Types of Cable Terminals

- Key Functions of Cable Terminals in Electrical Connections

- How Cable Terminals Impact Electrical Performance

- Factors to Consider When Choosing Cable Terminals

- Best Practices for Installing Cable Terminals

- Common Issues and Solutions Related to Cable Terminals

- Enhancing Cable Connectivity: Insights from Industry Reports on the SCHUTZKAPPE F4+7P Accessory and Its Impact on Performance

- FAQS

- Conclusion

- Related Posts

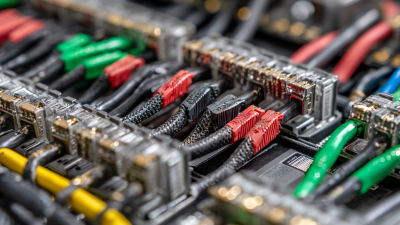

You know, in the world of electrical wiring, cable terminals often don’t get the attention they deserve. These tiny, behind-the-scenes components might seem minor, but they’re actually super important for making sure everything connects properly and safely. A good-quality cable terminal can really make a difference, boosting both safety and efficiency in your electrical setups.

Lots of industries, from auto manufacturing to telecoms, rely heavily on these little connectors. But here’s the thing— not all cable terminals are the same. Skimping on quality can lead to failures, and worse, potential hazards. Picking the right cable terminal isn’t just about specs on paper; it’s also about making sure it’s suitable for what you’re doing. It takes a bit of know-how to get it right.

At ElectriTech Solutions, we put a big emphasis on quality. Our products are built to handle all kinds of conditions, no matter what. That said, we know there’s always room to improve. We really value feedback from our customers because it helps us keep getting better. It’s all about that continuous cycle of listening, improving, and delivering reliable electrical connections that you can count on.

The Importance of Cable Terminals in Electrical Systems

Cable terminals play a crucial role in electrical systems. They serve as the connection points for wires and cables. A secure connection is essential for efficient power transfer. Without reliable terminals, systems can develop faults. This can lead to overheating or even failure of the equipment.

Choosing the right terminal type is important. Different applications may require specific terminals. For example, some might need insulated options for safety. Others could demand durable materials for heavy-duty use. It's easy to overlook these details in the excitement of a project. But mistakes can lead to costly repairs or unsafe conditions.

Installation is another area that needs attention. Improperly installed terminals can cause issues down the line. It’s vital to ensure that connections are tight and secure. When working with electrical systems, taking a moment to double-check connections can make a big difference. Simple oversights often lead to bigger problems later. Each step matters in creating a safe and efficient system.

Importance of Cable Terminals in Electrical Systems

Understanding Different Types of Cable Terminals

Cable terminals are essential components for reliable electrical connections. They come in various types, each designed for specific applications. For instance, compression terminals provide strong, durable connections. These are often used in commercial settings where high electrical loads are present.

The variety of terminals includes ring, spade, and fork types. Data indicates that about 40% of electrical failures are due to poor connections. This emphasizes the importance of choosing the right terminal for your project. A ring terminal can be ideal for connections needing permanence. Alternatively, spade terminals allow for quick disconnection, which is useful in dynamic environments.

Installing the wrong terminal can lead to issues. Improper fit or size can result in heating and even failure over time. Each terminal type has specifications you shouldn't overlook. Research shows that a significant portion of electrical mishaps stems from outdated or inappropriate hardware. Awareness of these risks is key for ensuring safety and efficiency.

Key Functions of Cable Terminals in Electrical Connections

Cable terminals play a crucial role in ensuring reliable electrical connections. They serve as the critical point where wires connect to devices or other wires. This connection can affect the performance and safety of an entire system. A poorly chosen or improperly installed terminal may lead to issues like overheating, increased resistance, or even short circuits.

Properly designed cable terminals facilitate easy installation and provide mechanical support. They minimize wear and tear over time, which is vital for long-term use. The material of the terminal also matters, as it can impact conductivity. Using corrosion-resistant materials can enhance longevity. An overlooked aspect, however, is compatibility with wire gauges. A mismatched size can lead to inadequate connections.

Regular inspection of cable terminals is essential. Signs of damage or corrosion might not be immediately visible. This oversight can lead to failures that not only disrupt operations but can also create safety hazards. Hence, recognizing the importance of these small components in electrical systems can significantly enhance safety and efficiency. Attention to detail is key.

How Cable Terminals Impact Electrical Performance

Cable terminals are often overlooked in electrical setups. However, they play a critical role in overall performance. Poor connections can lead to resistance, causing overheating. If a terminal corrodes, the result is a significant drop in efficiency. Small details, like the quality of materials used, can make a big difference.

The impact of cable terminals extends beyond physical connections. They influence signal integrity and power distribution. A loose or damaged terminal can introduce noise into the system. This interference can disrupt sensitive equipment. Precision in making these connections is vital.

Each terminal should be compatible with the cable type. Design matters too. Some terminals are bulkier than others. This can pose space issues in tight installations. A terminal that looks good might not always perform well. It's essential to balance aesthetics with functionality. Regular checks can help in identifying potential issues early.

Reflecting on the importance of these components can lead to improved electrical performance.

Factors to Consider When Choosing Cable Terminals

When selecting cable terminals, several critical factors come into play. One key consideration is the material. Copper and aluminum are the most common choices. Copper provides excellent conductivity but costs more. Aluminum, while lighter and cheaper, may require larger sizes to carry the same current. According to industry reports, using the right material can improve efficiency by up to 15%.

Another important factor is the terminal type. Crimped terminals versus soldered terminals each have their own advantages and disadvantages. Crimped connections can provide a robust and vibration-resistant solution, while soldered connections may offer a cleaner connection. A recent study indicated that crimped terminals tend to have a lower failure rate in high-stress environments.

Moreover, environmental factors shouldn’t be overlooked. Corrosive environments demand terminals designed for resilience. Choosing improperly can lead to connection degradation. A staggering 30% of electrical failures stem from inadequate terminal selection. Always assess the application and intended use before making a decision. Asking the right questions often reveals more than a quick choice.

Best Practices for Installing Cable Terminals

When it comes to electrical connections, cable terminals play a crucial role. They ensure a secure and conductive pathway for electricity. Properly installed terminals can prevent issues like overheating and short circuits. It's essential to handle them with care. Always choose the right size and type for your specific wire. A loose connection can lead to voltage drops and other failures.

Installation requires attention to detail. Stripping the wire too much can expose excess metal. This increases the risk of shorts. For reliable connections, use the correct crimping tool. A poorly crimped terminal can fail when you need it most. Make sure the wire gets fully inserted into the terminal before crimping.

Inspect your work after installation. Look for any visible gaps or loose fits. It’s not uncommon to miss small issues at first glance. Regular maintenance is key to long-term performance. Keeping connections clean from dust and corrosion should be part of your routine. In a world where every connection counts, small oversights can lead to bigger problems down the line.

Common Issues and Solutions Related to Cable Terminals

Cable terminals are vital for ensuring reliable electrical connections. However, several issues can arise, affecting their functionality. One common problem is corrosion. Moisture and contaminants can lead to rust, reducing conductivity. This makes connections weak. Regular inspection can help identify early signs of corrosion, allowing for timely action.

Another frequent issue is mechanical stress. Over-tightening can damage terminals, leading to poor connections. Conversely, under-tightened connections can cause arcing and overheating. Maintain a balance when securing terminals. It's essential to use the right tools and techniques for tightening.

Wire insulation can also be problematic. Damaged insulation may expose bare wires, posing safety risks. This situation can create short circuits or even electrical fires. Regularly check for insulation integrity. If discovered, replace the terminals or wires promptly. These preventative measures can enhance safety and efficiency in your electrical system.

Enhancing Cable Connectivity: Insights from Industry Reports on the SCHUTZKAPPE F4+7P Accessory and Its Impact on Performance

The SCHUTZKAPPE F4+7P accessory has garnered attention in recent industry reports for its significant enhancements in cable connectivity and overall performance efficiency. With the increasing demand for reliable and high-performance connectivity solutions, the integration of advanced features in accessories like the F4+7P is proving to be a game-changer. Industry analyses indicate that products utilizing innovative designs and advanced materials can improve signal integrity and reduce transmission losses, making them essential for modern applications.

The use of a round DIN flip connector tail cover highlights the importance of protective accessories in maintaining connection quality. Enhancing cable connectivity through such accessories not only ensures the longevity of the cables but also minimizes the risks of downtime caused by connectivity issues. Industry reports show that implementing these connectors can lead to a reduction in failure rates, with tested products demonstrating up to a 20% increase in performance stability. Furthermore, manufacturers employing ISO 9001 and IATF16949 management systems guarantee adherence to high-quality standards, further reinforcing the reliability of their products.

Fast delivery times and effective after-sale service play a critical role in customer satisfaction and trust within the industry. Companies focusing on rapid response to orders and comprehensive support post-purchase can significantly impact their competitive edge. Reports suggest that customers are more inclined to choose suppliers who not only provide quality products but also prioritize service efficiency, thus enhancing the overall user experience and promoting loyalty in the market.

FAQS

: Evaluate your needs and budget. Check product reviews for insights.

Look for verified customer feedback. Compare specifications rigorously.

Contact customer support immediately. Keep the packaging for returns.

Many products come with a warranty. Verify the duration and terms.

Most sellers provide tracking numbers. Check your email for updates.

Common methods include credit cards, debit cards, and online wallets.

Return policies vary. Read the policy carefully before purchasing.

Check tracking information first. Contact support if it’s excessively delayed.

Cancellation policies differ. Reach out to customer service quickly.

Generally, yes. Use secure connections and credible sites for safety.

Conclusion

Cable terminals are crucial components in electrical systems, playing a vital role in ensuring reliable and efficient electrical connections. Understanding the different types of cable terminals and their key functions is essential for optimizing electrical performance. Factors such as material, size, and application should be carefully considered when selecting the appropriate cable terminal to meet specific needs.

Proper installation practices are equally important, as they can significantly reduce common issues related to cable terminals, such as poor connectivity and electrical failures. By adhering to best practices, users can enhance the performance and longevity of their electrical systems, thus preventing potential problems down the line. Overall, a well-chosen and properly installed cable terminal can make a significant difference in the reliability of electrical connections.

Related Posts

-

5 Essential Factors to Consider When Choosing Best Cables And Connectors

-

Ultimate Guide to Choosing the Right Terminal Block Connector for Your Needs

-

7 Top Benefits of Using Cable Wire Connectors for Streamlined Electrical Projects

-

How to Select the Best Connector Cable for Your Global Supply Chain Efficiency

-

Innovative Car Cable Connectors Showcased at 2025 China Import and Export Fair

-

Unveiling China’s Manufacturing Excellence: Your Gateway to the Best Electrical Terminals Globally

Blog Tags: